Better batteries possible with alternative electrodes

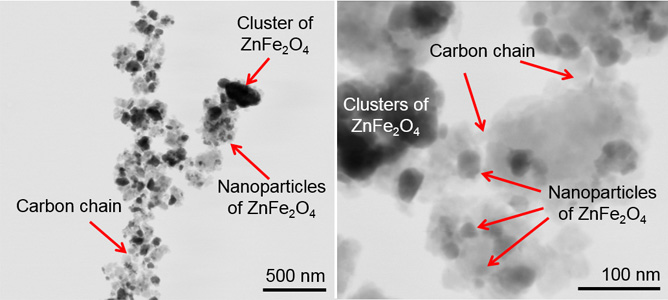

Low magnification (left) and high magnification (right) STEM images of ZnFe2O4-carbon nanocomposite electrode for Li-ion batteries.

April 2015

Lithium-ion batteries are currently used in every-day devices such as portable electronic devices and power tools. They are also of interest for other emerging applications including electric vehicle batteries and for storage of energy harvested by solar cells.

Graphite and lithium cobalt oxide are currently used in conventional lithium-ion batteries but these batteries may suffer from relatively small storage capacity. As a result, portable devices have limited time of use between recharges and the operation time of their battery decreases over the life of the battery. Similarly, electric vehicles are limited by the operation of their batteries and have limited driving range.

To improve the both the charge capacity and life span of these batteries, alternative materials for battery electrodes are currently being investigated by MCN Technology Fellow, Dr. Alexey Glushenkov from Deakin University. These new materials are expected to store more charge and remain active for longer periods of time. To select and optimise these materials, characterisation by electron microscopy is required to understand their structure and performance.

Through using the FIB-SEM at MCN which is fitted with Scanning Transmission Electron Microscopy (STEM) detectors, Dr. Glushenkov is able to select and study new electrode materials for Li-ion batteries. The electrode materials are synthesized by his team at Deakin University in joint effort with Dr. Md Mokhlesur Rahman. The unique capability of the FIB-SEM instrument available at MCN is its ability to perform scanning electron microscopy (SEM) and STEM on the same specimen simultaneously. This allows researchers to understand the morphology of materials, their structure and composition at the same time, without the need to use multiple instruments. In addition, the focused ion beam available on the instrument can precisely slice specimens when required.

The team has recently produced a novel nanocomposite material in which zinc iron oxide is mixed with carbon. Zinc iron oxide is seen as an interesting electrode material for batteries but it usually cannot deliver sufficient charge storage and its ability to operate in a battery deteriorates quickly. However, the composite of zinc iron oxide with carbon developed by researchers at Deakin can store a large amount of charge and retain its charge storage ability for an extended life-span. Through use of the FIB-SEM instrument at MCN, the team have established that the attractive charge storage ability was achieved due to a unique nanostructure of the composite which consists of chains of carbon material decorated with oxide nanoparticles (refer to STEM images above).

This project holds great potential for the development of better electrode materials for batteries and, as a result, more reliable, longer lasting and cheaper batteries with higher charge storage capacities. In turn, this benefits portable electronic devices, power tools, electric vehicles, integrated solar cell-battery packs and many other applications.

The team expects to apply the FIB–SEM instrument available at MCN to studying electrode materials not only for lithium-ion batteries but also for new, unconventional types of batteries. In particular, sodium-ion are currently emerging as a new type of batteries for many applications.