Packaging

Packaging is often the final step in making a nanofabrication device functional as a stand-alone device or in the context of an integrated system.

| Process | Make & Model | Defining features |

| Dicing saw | DISCO 3350 | Capable of handling a max size of 8in diameter substrate and a max thickness of 5mm. Also capable of performing circle cut, trimming down circular shape samples and chopper cut. |

| Femtosecond Laser System | 3D Micromac microPRO XS | fs-Carbide laser with 40W power, 3 wavelengths; 343nm, 515nm and 1030nm; Capable of laser cutting for a wide range of materials, including diamond; laser micro-machining; and machining silicon structures on a micro-scale. |

| Bonding | FS Bondtec - Series 58 Wedge and Ball Bonder | Used for both gold and aluminium bonding. |

The process:

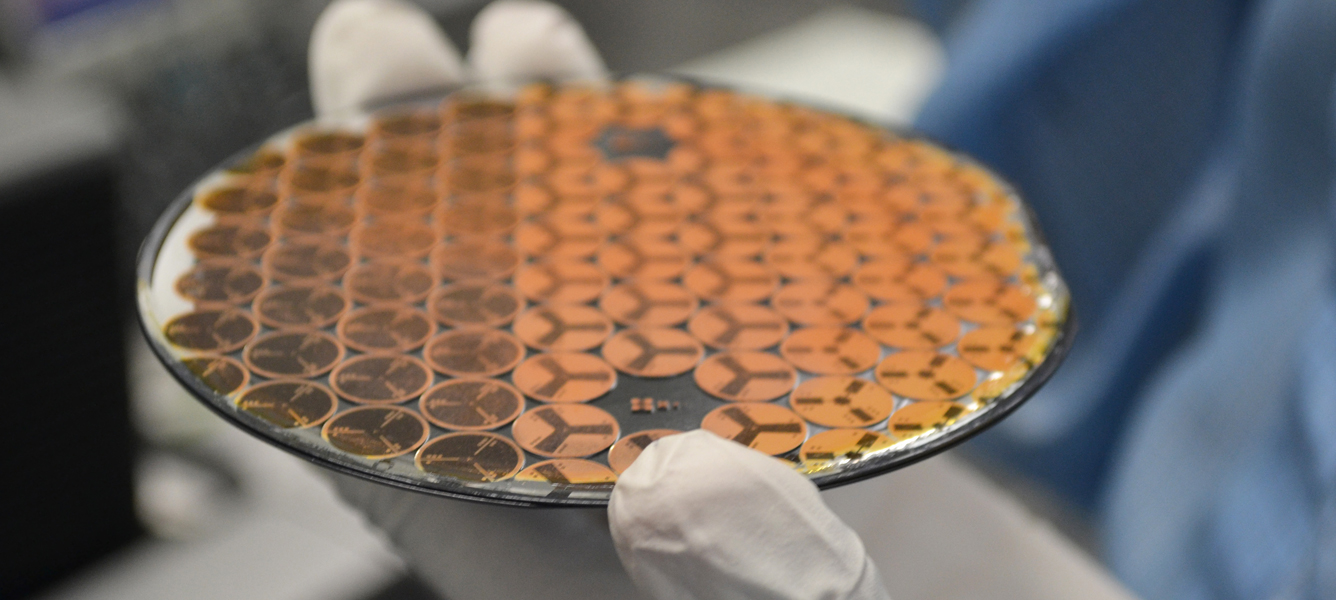

Nanofabricated devices are generally made in batches on wafers and need to be separated or packaged before use. This separation can be achieved through wet or dry dicing. In a wet dicing operation, a precision, high-speed, diamond impregnated blade is used to mill narrow grooves between the devices either partially or completely through the wafer.

During this process, water is circulated over the cutting surface to cool the blade and prevent the liberation of dangerous particulates into the air. Materials which would be damaged by water are diced using a dry process known as scribing. Scribing utilises a diamond tipped stylus which is drawn across the wafer surface creating lines of high-stress which are later broken over precision fulcrum.

After separation, the devices may need to be electrically connected to an interface via a process of gold or aluminium wire bonding.

The uses:

Dicing and bonding are necessary for the completion of most nano and microfabrication devices.

The Instruments:

The MCN houses two wafer dicing instruments - the Disco 3350 automated dicing saw, for wet dicing processes and a soon to be installed Femtosecond Laser System from 3D Micromac. Femtosecond lasers are utilized for a wide range of applications including micromachining, spectroscopy, nonlinear optics, and ultrafast imaging, among others.

For bonding, MCN’s wire bonder include Wedge and Ball Bonders. They are used for both gold and aluminium bonding.

MCN also houses the FS Bondtec - Series 58 Wedge and Ball Bonder, with two exchangeable bond heads. The Ball-Wedge Bonder 5810, used for gold wire bonding and the Deep-Access Wedge-Wedge Bonder 5832 used for both gold and aluminium bonding.