Cantilevers to assist with fluid characterisation

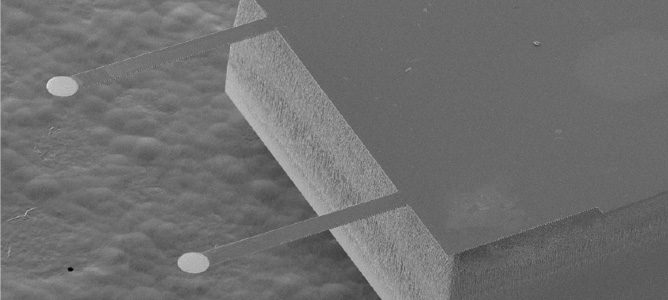

Scanning Electron Microscope Image of Si Cantilever

October 2011

MCN’s Doug Mair has worked collaboratively with Dr Raymond Dagastine from the Particulate Fluids Processing Centre at Melbourne University to develop silicon cantilevers to continue the already extensive research performed by his group into the area of bubble and oil drop dynamics. The goal of the project was to design and manufacture silicon cantilevers with different spring constants and gold paddle sizes to assist with characterisation of deformable drops on Confocal and AFM systems.

The project went through several stages, from concept to design through to process development. All process development has been completed and the first wafer of cantilevers has been successfully fabricated and tested. This project brought together many of the capabilities of MCN including front side and backside pattern alignment, chrome/gold evaporation, deep reactive ion etching (Bosch Process), chemical processing through to final characterisation of product on AFM all under the one roof.

The project has been a great success and opens the door to a large range of cantilever based designs.