Providing a platform for muscle stem cell therapy

A team of Victoria-based researchers is taking tips from Mother Nature to make muscle stem cell (MSC) therapy a more effective and affordable option for treating degenerative diseases. The group is attempting to increase the efficiency of stem cell proliferation by introducing nerve-like stimulations into the environments in which the cells grow.

If it works, the platforms could make MSC therapy an affordable option capable of helping manage some of the most inhibitive degenerative conditions, such as duchenne muscular dystrophy – a muscle wasting disease which leads to a reduced life expectancy and affects one in 3,500 males.

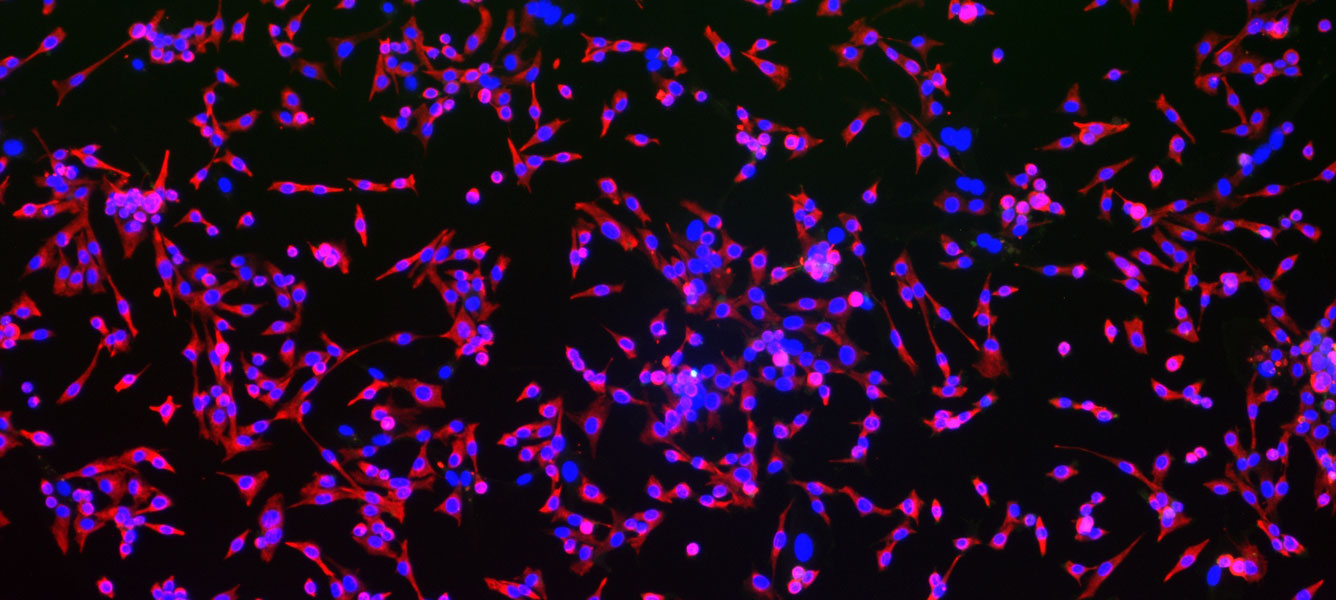

MSC therapies require stem cells to be implanted into a patient to replace damaged or dead tissue. Such treatments require the cultivation of a large population of healthy stem cells in order to be successful.

[perfectpullquote align=”right” cite=”” link=”” color=”#82bc43″ class=”” size=”18″]“Currently, the allylamine and acrylic acid films are 3nm thick. The data hasn’t been fully analysed but even a coating this thin reduces the conductivity of polypyrrole,” – Uma Suparamaniam[/perfectpullquote]

It’s been known for a while that the quality of a batch of stem cells is highly sensitive to the environmental conditions in which it was grown or cultured. Provide the wrong “mood” and the cells may stop dividing or worse, die off. The end result is a less effective and more expensive course of treatment.

Uma Suparamaniam, a PhD student at the ARC Training Centre in Biodevices at Swinburne University of Technology, is investigating whether electrical stimulations that replicate nerve impulses will increase stem cell proliferation. She is currently working with St Vincent’s Hospital in Melbourne and engineers at the ANFF-Vic Biointerface Engineering Hub to create the modified culturing platform for the cells.

To introduce the stimulation, the team selected a biocompatible and electrically conductive material called polypyrrole. They then coated this with either polymerised allylamine or acrylic acid – substances known to encourage stem cell growth.

Uma and her colleagues varied the thicknesses of the allylamine and acrylic acid films to find the right balance between having enough of these substances in the coated surfaces, and allowing the electrical stimulation from the polypyrrole to act on the cells. “The surfaces need to be thick enough to have a high enough density of functional groups to influence cell growth, but thin enough to maximise conductivity,” Uma explained.

“The idea is to preserve the natural roughness of the polypyrrole as well as its electrical properties. This means thin coatings are preferred,” she continued. “Currently, the allylamine and acrylic acid films are 3nm thick. The data hasn’t been fully analysed but even a coating this thin reduces the conductivity of polypyrrole.”

[perfectpullquote align=”right” cite=”” link=”” color=”#82bc43″ class=”” size=”18″]“The advantage of plasma polymerisation is that, unlike other methods, deposition is substrate independent and can thus be used to coat a wide variety of samples,” – Karyn Jarvis [/perfectpullquote]

The films were created using the Biointerface Engineering Hub’s plasma reactor. The device produces thin films by fragmenting a selected molecule with a plasma and coating everything inside the reactor with it, including the desired surface. It’s possible to vary the chemistry of the film by changing the conditions within the reactor, and the thickness of the film can also be changed by controlling the deposition time.

The versatility of the process also figures heavily in the group’s decision to use it – and also opens the method to the possibility of mass production.

“There are a number of wet chemistry methods that can be used to create organic thin films but the advantage of plasma polymerisation is that, unlike other methods, deposition is substrate independent and can thus be used to coat a wide variety of samples,” explained Karyn Jarvis, a research engineer at ANFF-Vic’s Biointerface Engineering Hub who assisted the project. “There are some companies that have developed industrial scale plasma reactors to enable the coating of commercial quantities.”

Uma was trained by Karyn to run the plasma reactor independently so she could produce her own films, and gain skills for her PhD. The facility’s staff also taught Uma to conduct ellipsometry experiments that could be used to determine the thickness of her plasma polymer films.

The team’s work is already providing indications that could improve the success of MSC proliferation. “While the experiments are ongoing, we have some preliminary results that suggest that acrylic acid surfaces are more favourable than allylamine surfaces for cell adhesion,” Uma added. “Such information may be used to dictate future direction of the experiments.”