Rapid prototyping to understand particle diffusion

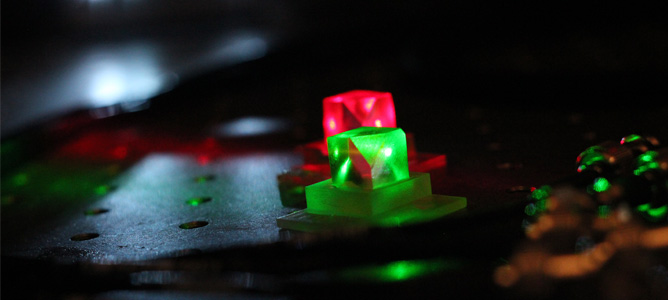

Creation of a printed optics component using MCN’s Objet Eden 3D printer.

Illustrating the diffusion of light passing through two un-finished optical cubes.

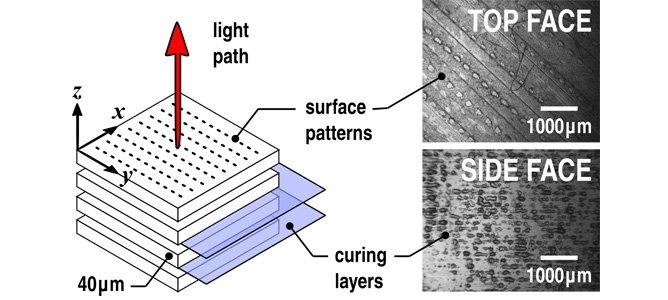

The Objet Eden 260v has a resolution of 40-60 microns, so unfinished surfaces appear quite rough at 10x magnification.

April 2015

A team of researchers from Melbourne University have been using laser-based microscopy techniques to understand the diffusion of particles during advanced self-assembly and transport processes, such as carbon nanotubes settling at an interface or the alignment of rod-like zinc oxide crystals during solar cell fabrication. Leading the project, MCN Technology Fellow, Ray Dagastine and PhD student, Christopher Bolton are focusing on the a critical element of this work which is the fabrication of specially designed optical prisms which are used to control light. The traditional approach has been to design prisms and send specifications to a glasscutter, often internationally, a process which is expensive and slow and where design-intent is often lost in translation.

Using MCN’s Objet Eden 260v 3D printer, the team are able to fabricate complicated objects rapidly by using optically transparent materials. Through exploring various approaches to printing optical components, as well as experimenting with different materials and settings, they have achieved optimum printing results which would not have been possible through a commerical print supplier. The team has also been refining techniques for polishing printed objects to a standard that permits their use with Class-3A/B lasers which will greatly accelerate prototyping of a new microscopy technique currently under development.

Advanced rapid prototyping tools of this kind enables and accelerates research that might otherwise be considered impractical from a fabrication standpoint. Reduced time and cost in fabricating complicated optical components opens to door for greater innovation, and more widespread use of advanced microscopy techniques in research and teaching environments.

In addition to providing state-of-the-art equipment and facilities necessary to fabricate these printed optical components, the network of experts and Technology Fellows residing at MCN has helped to drive this project forward