Small fibres solving big problems

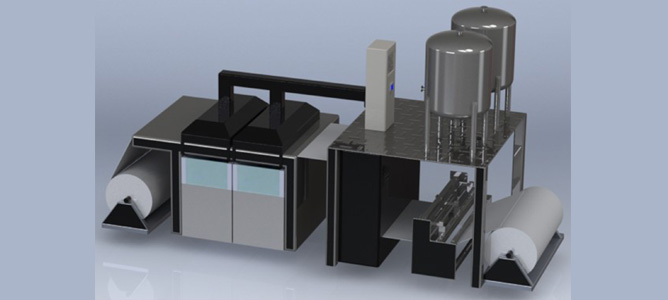

The design of the needless electrospinning machine created at Deakin University

February 2014

The creation of fibrous materials is proving advantageous in a range of applications, from apparel fabrics and upholsteries to advanced composites, filters and biomedical scaffolds. The diameter of the fibres in these fabrics plays an important role in determining their functions and applications.

The smaller the fibres, the more potential they have in many fields. For example, the efficiency of fibrous filters increases with reduced fibre diameter and tissue scaffolds made of smaller fibres can provide better cell growth environment.

However, due to the difficulties associated with producing nanofibres on a large scale, commercial fibres typically tend to fall within the micron range, rather than the nano range.

Several techniques have been developed to increase the large scale production of nanofibres, the most versatile of which is electrospinning. Electrospinning is distinct from other nanofibre production techniques in its versatility to process different polymers, ability to control fibre diameter, morphology, orientation, component and fibrous structure.

However, the key challenge in electrospinning is low outputs due to the use of needle nozzles to produce the nanofibres. Prof Tong Lin, Dr Haitao Niu and Dr Jian Fang at Deakin University are aiming to solve this critical problem by using needle-free fibre generators to mass-produce quality nanofibres.

Through funding support from ANFF, Prof Lin, Dr Niu and Dr Fang have been able to successfully construct coil-based, needleless electrospinning machines, which have much higher fibre productivity than needle-based electrospinning. This manufacturing platform represents a breakthrough in production of quality nanofibres as it allows production of nanofibres on a large scale and development of various nanofibre products. Nanofibre webs can be produced continuously with a width up to 2 metres.

Some possible applications for these nanofibes include face masks and respirators for filtration of pollution from airborne particles. Microfibre masks are not adequately able to protect people from inhaling particles smaller than 2.5 microns, a serious issue in many industrial environments and countries. By adding a thin layer of nanofibre web into face masks, the filtration efficiency can be increased dramatically to block almost all tiny particles, thus providing best possible protection.

Another application of electrospun nanofibres is in Lithium ion batteries as separators. Battery separators, which are sheets of porous nanoconducting material, prevent short circuiting of the batteries by preventing the positive and negative plates from bending and touching. When made of electrospun nanofibres, they can extend the battery lifetime by 25%, without sacrificing electrical performance.

Furthermore, nanofibres electrospun from piezoelectric polymers show excellent ability to convert mechanical energies into electric power. The researchers found that needleless electrospinning can produce these power-generating nanofibres with much higher productivity than conventional needle electrospinning.

This research provides opportunities for local industry to manufacture nanofibres and develop nanofibre products. This would strengthen the technical ability of Australian local industry in producing nanofibre products, such as highly efficient air filter, face masks, Lithium ion battery separators and noise absorbers.

The next stage of this research will be focused on the development of these nanofibre-based products in collaboration with industry. Efforts will also be made to refine the performance of the electrospinning machines.