Colour coded chemicals

A team led by researchers at the La Trobe Institute for Molecular Sciences (LIMS) in collaboration with RMIT has been investigating a novel way to analyse chemicals using visible light.

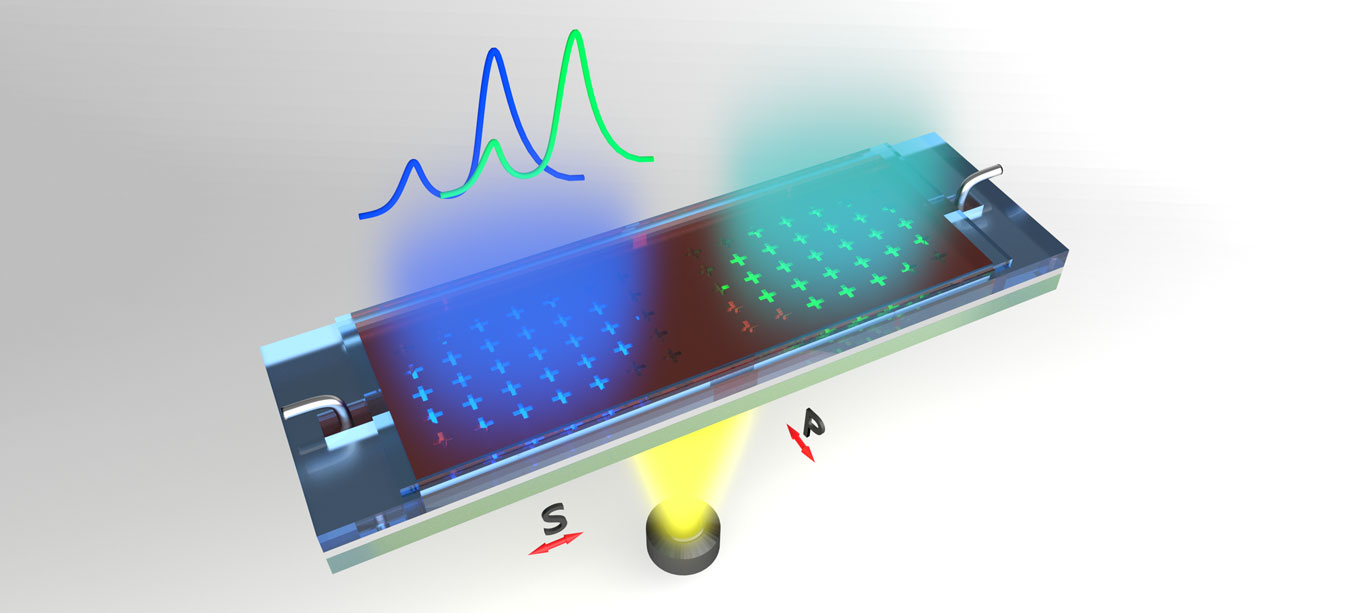

The device uses the interaction between photons and electrons to filter out colours to create an ‘optical barcode’ that is specific to a sample and can be compared to a library of known material signatures.

The group’s tuneable and potentially portable device can quickly help to identify concentrations of chemicals and can be used for a range of sensing applications including monitoring water pollutants and inspecting soil quality. Because the device does not chemically modify the solution being analysed it has the potential to be used for real-time monitoring in applications including food and pharmaceutical production.

Using microfluidic channels, the device directs a liquid sample over a quartz surface with a silver coating. The coating features an array of nanometre-sized holes which allow light to pass through the device. To identify a sample, broadband light is passed through the liquid and is observed from the other side. Due to a phenomenon described by a branch of physics called plasmonics, all but one colour of light is filtered out as it passes through the liquid and the array depending on the refractive index of the sample.

The refractive index of a material is an intrinsic property that defines how fast light can pass through it. This refractive index can be used to help differentiate chemicals, so comparing the wavelength of the transmitted light to a known library can be used to help identify a sample.

This form of chemical sensing has been tested before, but it has run into problems detecting the minute changes in colour that occur for different chemicals.

The issue has now been overcome, thanks to the LIMS/RMIT team’s breakthrough which came by changing the device to be sensitive to not just the refractive index of the sample, but to the incident orientation of the light (polarisation) as well. This introduces a way to create a chain of reference points that can be used to identify chemicals far more accurately than ever before using this technique.

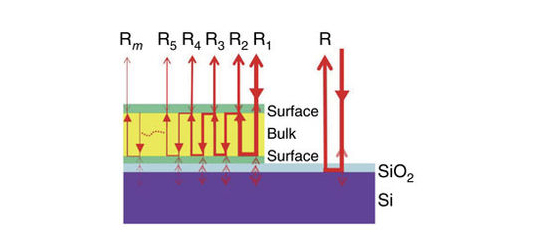

Plasmonic filtering relies on the fact that within the thin film of silver there is a “sea” of free elections. When the broadband light hits the surface, a particular wavelength of light resonates with these electrons depending on the distance between the holes in the coating and the refractive index of the sample to create a standing wave. Any light of this wavelength is allowed to pass through the holes, while all other light is absorbed or reflected by the silver layer. Historically, this type of sensing uses an evenly spread array of circular holes which means that it doesn’t matter what polarisation of light hits it.

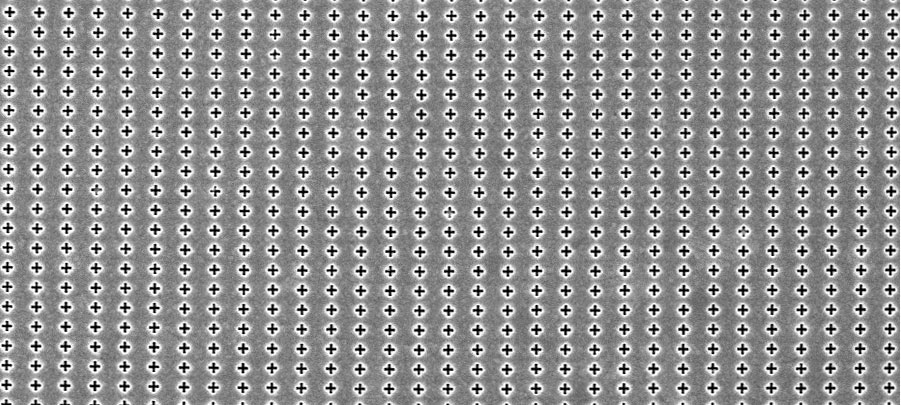

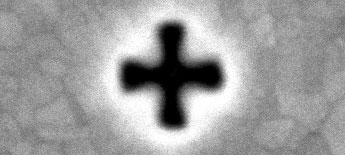

The team instead created an array that features cross-shaped holes, and then spread them at different distances in the x and y planes. This means that the wavelength of light needed to excite the electrons between the crosses in the x-direction is different to the one needed to excite the electrons in the y-direction.

Using light that was polarised to align with either the x or y directions therefore produces different colours once the plasmonic filtering has occurred and effectively creates two reference points to compare to other materials. By testing a range of different angles of polarised light for the same sample and recording the series of colours produced then creates a far more specific signature to be compared to a library of known results.

The team used MCN’s Electron Beam Evaporation equipment to deposit the silver coating, before using the Centre’s Focused Ion Beam Scanning Electron Microscope (FIB-SEM) to mill out the nanometre-sized crosses.

“Data collection was also carried out at MCN using the microspectroscope equipment. Every step of the process from producing the devices to analysing the data involved support and collaboration with MCN,” said Dr Daniel Langley, who was the first author of the study.

The team now plans to use this technology to develop a standalone chemical sensor for probing local environments at the microscale in a variety of applications. Initially though, the aim is to tailor the device to agricultural applications, monitoring contamination in plants and soils.

“We would like to improve the sensitivity of the technique even further, refining the device structure and exploring different materials in the active layers.” Daniel said. “These developments will require close interaction with ANFF staff as we work out the possibilities at MCN.”

“We would also like to develop a library of ‘optical barcodes’ for different chemicals and mixtures – here ANFF’s broad network could be essential for making the research and industry connections we need to direct this technology towards the highest impact applications with the greatest societal benefit,” said A/Prof Brian Abbey, a co-corresponding author on the paper.

Automatically assembling nanolenses

A team of researchers has created a scalable production method for a class of nanoscale lenses using the electrostatic forces between charged nanoparticles, enabling wider application of the technology.

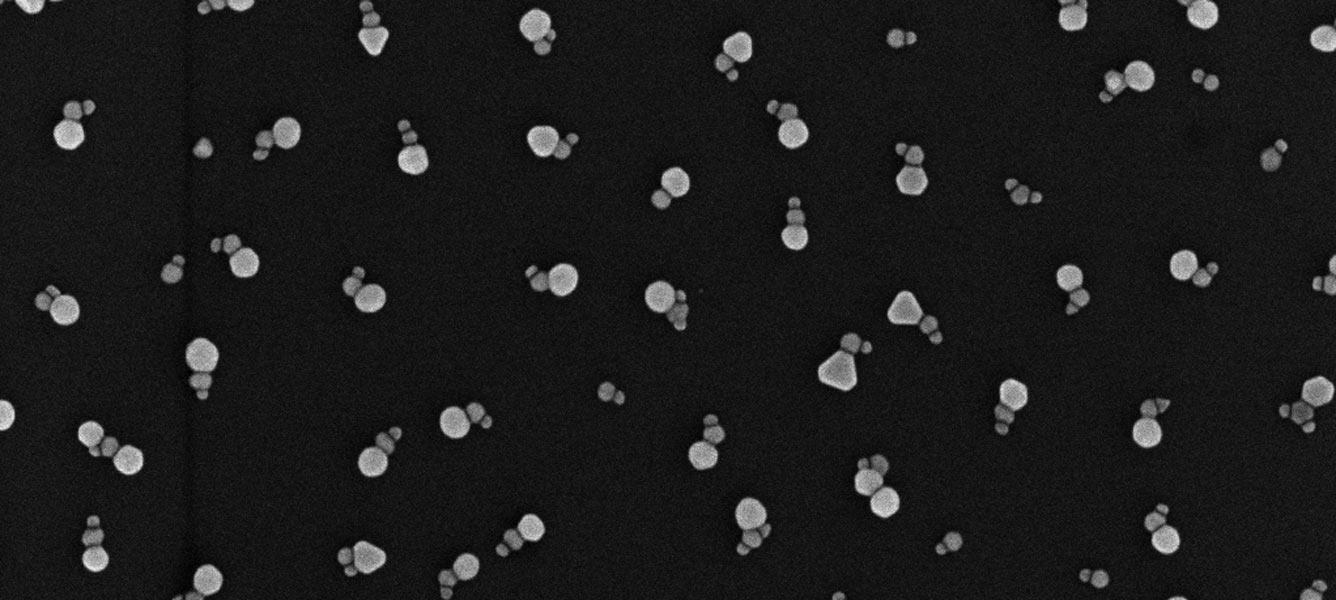

These nanolenses use the gaps between triplets – or trimers – of different sized nanoparticles to focus light.

They are showing enormous promise in a range of optical and sensing applications due to their minuscule size and very high-yield enhancement. However, an expensive and laborious production process has limited their widespread uptake.

Dr Julian Lloyd, lead author of the research, and his colleagues’ method uses induced electrostatic forces to self-assemble the gold nanoparticle triplets. The process was developed at Monash University, Monash Centre for Electron Microscopy and the Melbourne Centre for Nanofabrication, ANFF VIC’s flagship facility and ANFF’s headquarters.

The method enables production of these trimers with a more than 60 percent yield, quantities that have never been achieved before, and removes the need for expensive “top-down” fabrication techniques traditionally used that inhibit the scalability of the fabrication process.

An illustration of the trimers focusing light. Credit: Soon Hock Ng

Julian’s trimers are short strings of nanoparticles 20nm, 30nm and 50nm in diameter. In his paper published in ACS Nano, Julian explains that by placing differing surface charges on the nanoparticles, the structures draw themselves into place.

Using a positively charged substrate as a base, the team add a number of negatively charged 30nm particles which neatly distribute themselves across the surface. Positively charged 20nm particles are added, each attracted to a 30nm particle, before a solution of positively charged 50nm particles is introduced. The particles align themselves because the 20 and 50nm particles repel each other, whilst both being drawn towards the centre 30nm particle.

“We can control the distance between individual trimers and also improve the trimer yield by tuning the surface charges,” Julian explained.

“As the whole assembly method relies on electrostatic interactions, it was vitally important to know the surface charges of the different components,” he continued. “The surface charge measurements were taken at the Melbourne Centre for Nanofabrication using the Centre’s Zeta sizer and a Zeta potential analyser.”

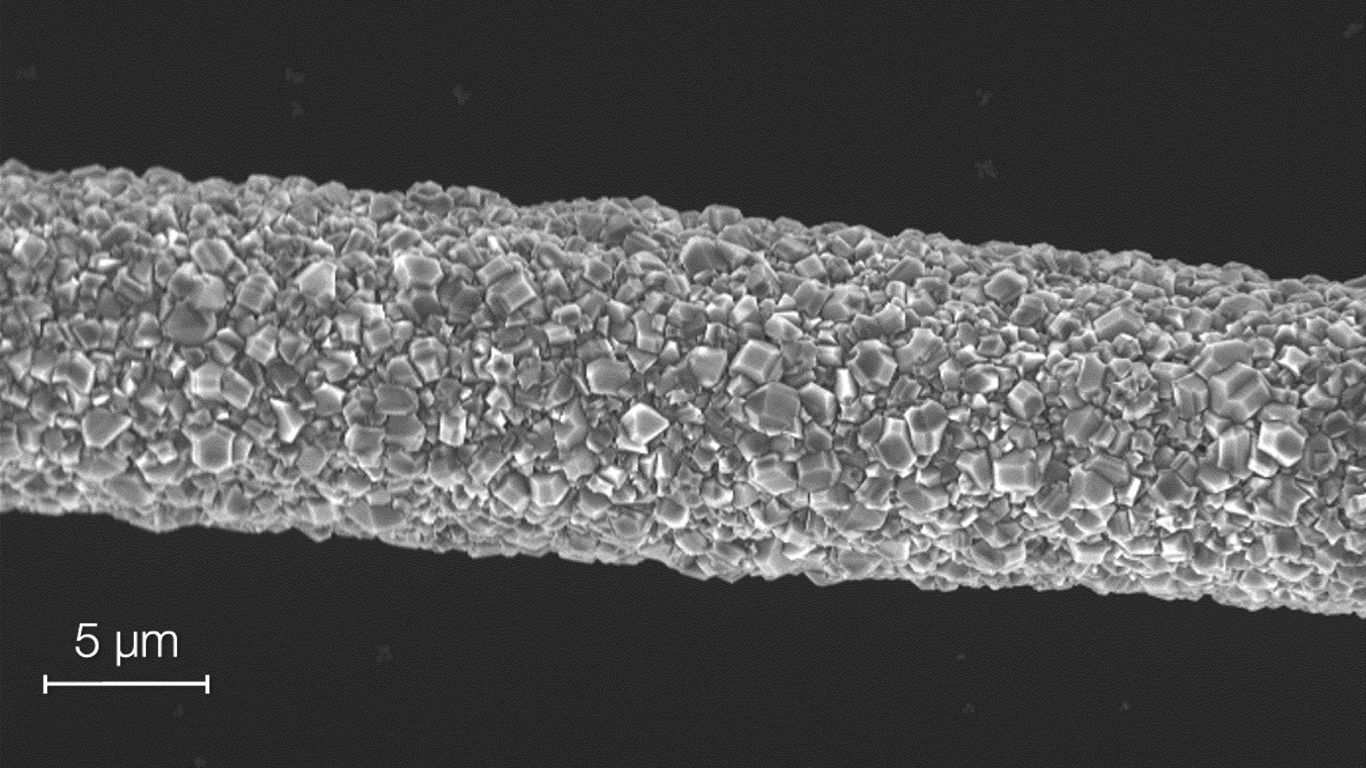

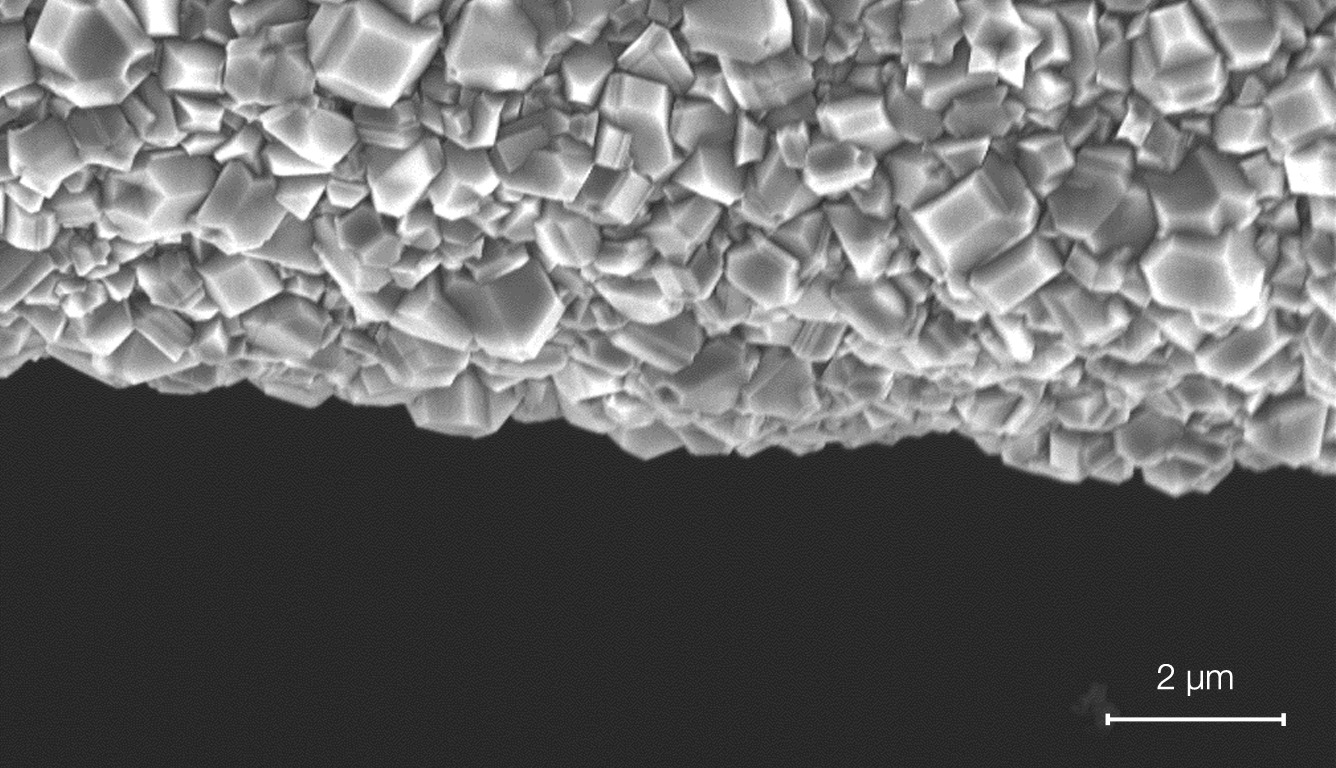

Nanofibre facemasks provide a breath of fresh air

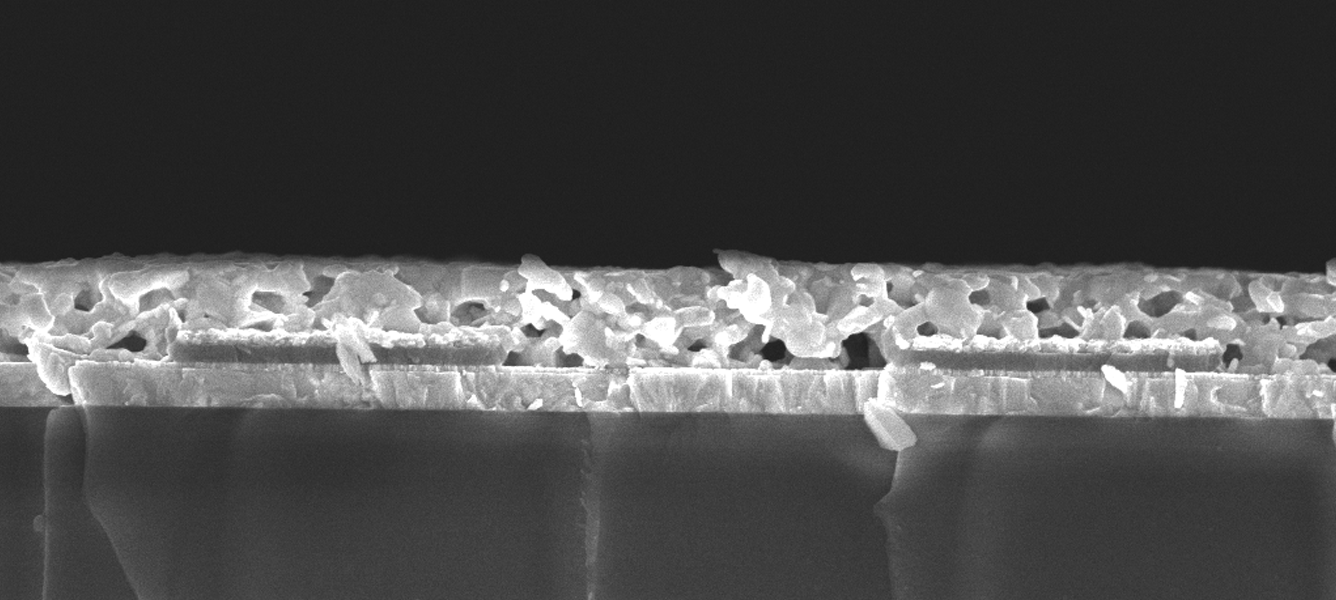

Deakin University’s Institute of Frontier Materials (IFM) has been working with Xinau Technology to develop a new type of nanofibre facemask that will replace traditional microfibre-based equivalents.

Air quality is on the decline in huge areas of the developed and developing world. The International Energy Agency attribute an estimated 6.5 million deaths per year to indoor and outdoor air pollution – it is reportedly the fourth largest threat to human health, after high blood pressure, dietary risks, and smoking. Pollutants that measure less than 2.5 microns (PM2.5) are a particular concern, their small size means they are able to penetrate deep into the lungs.

Facemasks are now commonly used in heavily affected areas, but conventional microfibre masks either don’t provide the necessary filtration or block air ow too heavily, making it hard to breathe.

As “smog seasons” become a regular occurrence, cities such as Beijing are seeing a huge number of residents turn to expensive, high-end masks to help them breathe easy.

A team at the IFM are now using ANFF VIC’s electrospinning equipment to create nanofibre-based masks that are drastically better at stopping inhalation of PM2.5 particles and provide very little breath resistance. The pilot electrospinning machine is able to prepare 2-metre-wide nanofibre sheets in a continuous manner and has a production capability of up to 1,000m2 per day.

“ANFF VIC’s needleless electrospinning machines at Deakin university made it possible to process large-size nanofibre nonwoven sheets with consistent structure.” – Professor Tong Lin

“When a layer of nanofibre nonwovens is inserted into conventional facemask, the breath resistance did not increase much, however, the capture efficiency for PM2.5 was significantly improved,” Professor Tong Lin, leader of the team at Deakin University, said. This means the team can make the filtering material thinner and more breathable, while still stopping up to 95% of airborne pollutants.

The key component to maintain high PM2.5 filtration efficiency is the nanofibre sheets, which are highly porous and have a large surface area.

“ANFF VIC’s needleless electrospinning machines at Deakin university made it possible to process large-size nanofibre nonwoven sheets with consistent structure,” Tong continued. “It also allows you to adjust the fibrous structure by changing the operating parameters such as voltage, spinning distance and polymer components.”

The team are currently working with Xinau to commercialise the technology.

Ultrathin holograms open doors to 3D displays

Providing a platform for muscle stem cell therapy

A team of Victoria-based researchers is taking tips from Mother Nature to make muscle stem cell (MSC) therapy a more effective and affordable option for treating degenerative diseases. The group is attempting to increase the efficiency of stem cell proliferation by introducing nerve-like stimulations into the environments in which the cells grow.

If it works, the platforms could make MSC therapy an affordable option capable of helping manage some of the most inhibitive degenerative conditions, such as duchenne muscular dystrophy – a muscle wasting disease which leads to a reduced life expectancy and affects one in 3,500 males.

MSC therapies require stem cells to be implanted into a patient to replace damaged or dead tissue. Such treatments require the cultivation of a large population of healthy stem cells in order to be successful.

“Currently, the allylamine and acrylic acid films are 3nm thick. The data hasn’t been fully analysed but even a coating this thin reduces the conductivity of polypyrrole,” – Uma Suparamaniam

It’s been known for a while that the quality of a batch of stem cells is highly sensitive to the environmental conditions in which it was grown or cultured. Provide the wrong “mood” and the cells may stop dividing or worse, die off. The end result is a less effective and more expensive course of treatment.

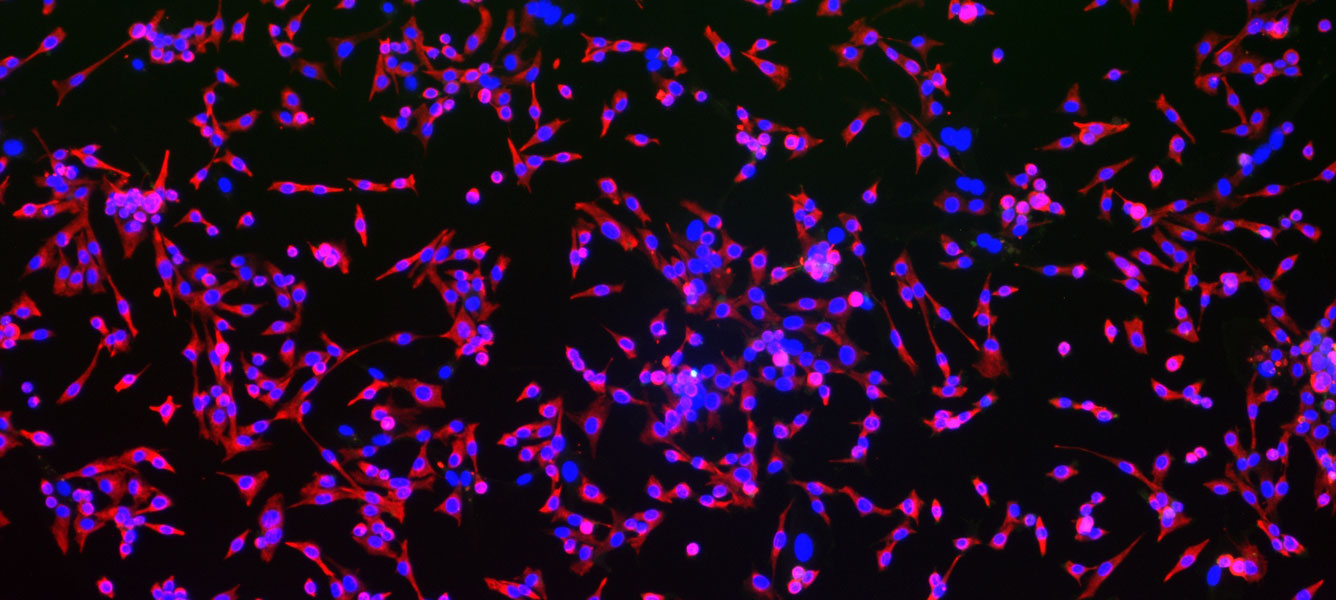

Uma Suparamaniam, a PhD student at the ARC Training Centre in Biodevices at Swinburne University of Technology, is investigating whether electrical stimulations that replicate nerve impulses will increase stem cell proliferation. She is currently working with St Vincent’s Hospital in Melbourne and engineers at the ANFF-Vic Biointerface Engineering Hub to create the modified culturing platform for the cells.

To introduce the stimulation, the team selected a biocompatible and electrically conductive material called polypyrrole. They then coated this with either polymerised allylamine or acrylic acid – substances known to encourage stem cell growth.

Uma and her colleagues varied the thicknesses of the allylamine and acrylic acid films to find the right balance between having enough of these substances in the coated surfaces, and allowing the electrical stimulation from the polypyrrole to act on the cells. “The surfaces need to be thick enough to have a high enough density of functional groups to influence cell growth, but thin enough to maximise conductivity,” Uma explained.

“The idea is to preserve the natural roughness of the polypyrrole as well as its electrical properties. This means thin coatings are preferred,” she continued. “Currently, the allylamine and acrylic acid films are 3nm thick. The data hasn’t been fully analysed but even a coating this thin reduces the conductivity of polypyrrole.”

“The advantage of plasma polymerisation is that, unlike other methods, deposition is substrate independent and can thus be used to coat a wide variety of samples,” – Karyn Jarvis

The films were created using the Biointerface Engineering Hub’s plasma reactor. The device produces thin films by fragmenting a selected molecule with a plasma and coating everything inside the reactor with it, including the desired surface. It’s possible to vary the chemistry of the film by changing the conditions within the reactor, and the thickness of the film can also be changed by controlling the deposition time.

The versatility of the process also figures heavily in the group’s decision to use it – and also opens the method to the possibility of mass production.

“There are a number of wet chemistry methods that can be used to create organic thin films but the advantage of plasma polymerisation is that, unlike other methods, deposition is substrate independent and can thus be used to coat a wide variety of samples,” explained Karyn Jarvis, a research engineer at ANFF-Vic’s Biointerface Engineering Hub who assisted the project. “There are some companies that have developed industrial scale plasma reactors to enable the coating of commercial quantities.”

Uma was trained by Karyn to run the plasma reactor independently so she could produce her own films, and gain skills for her PhD. The facility’s staff also taught Uma to conduct ellipsometry experiments that could be used to determine the thickness of her plasma polymer films.

The team’s work is already providing indications that could improve the success of MSC proliferation. “While the experiments are ongoing, we have some preliminary results that suggest that acrylic acid surfaces are more favourable than allylamine surfaces for cell adhesion,” Uma added. “Such information may be used to dictate future direction of the experiments.”

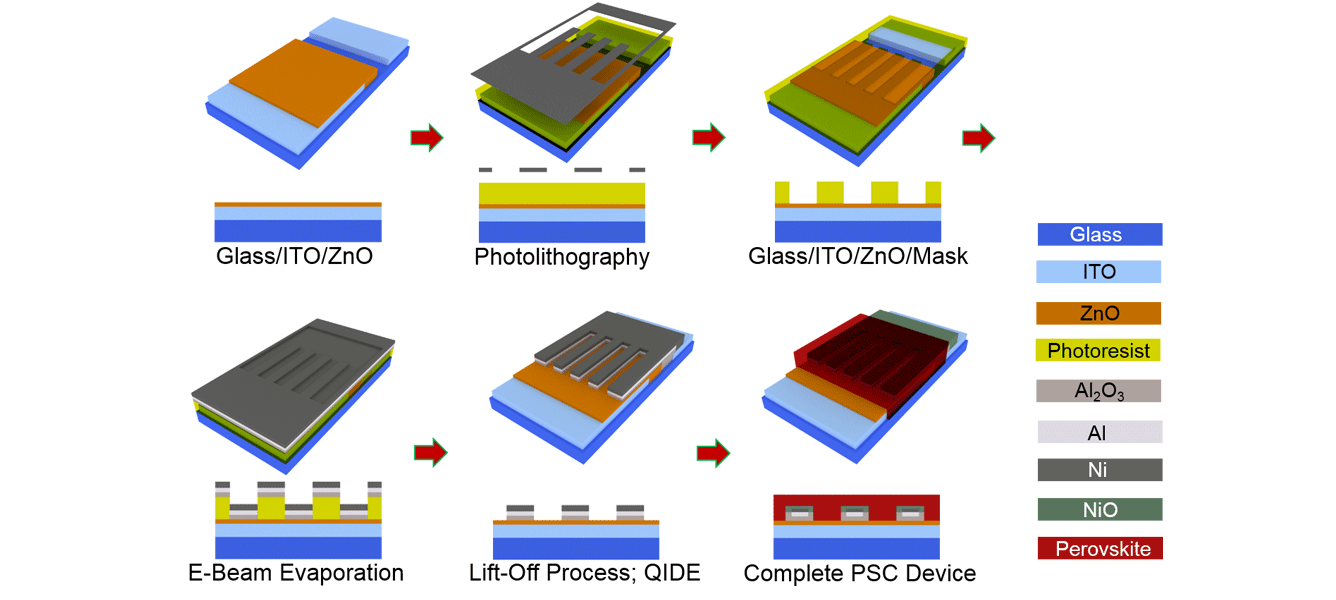

Creating back-contacted solar cells

Solar cells are one of the most promising and accessible mechanisms by which the country can reduce its carbon footprint. However, the technology is still maturing and inefficiencies remain a barrier to widespread usage.

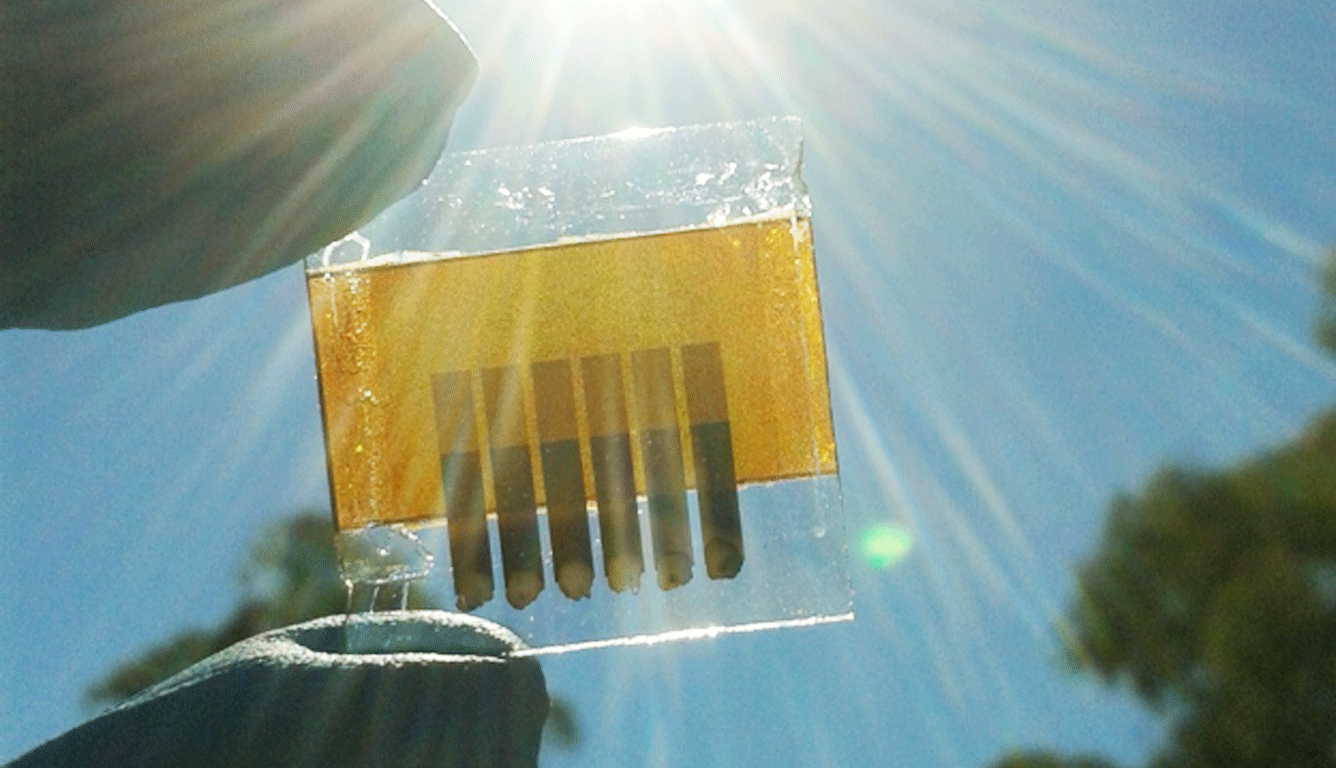

Now though, by combining the benefits of back-contacted solar cells with perovskite materials, researchers have achieved a much sought after pathway to more efficient photovoltaic devices.

Solar cells work by using a photovoltaic material to produce an electric current between an anode and cathode when illuminated by the sun. However, the way a cell is structured and the materials it’s built from can have a dramatic effect on its ultimate performance, and thus its relevance in real-world applications.

The two leading types of devices are currently back-contacted silicon cells and perovskite-based devices. They each have their own efficiency advantages, but also limitations.

Perovskite is a material which is incredibly good at taking in light and converting it to electrical energy. However, perovskite solar cells (PSCs) are currently built using a “sandwich structure”, which requires a conductive and opaque electrode above and below the photosensitive perovskite material, limiting the directions in which they can receive light, which reduces the overall device efficiency.

Back-contacted solar cells are the widely preferred method for collecting the electricity created by photovoltaic material. Building the electrodes into an underlying structure of the light-sensitive material reduces transmission losses associated with top-side electrodes and allows it to be illuminated from all sides. Back-contacted silicon photovoltaic cells have already been manufactured and are commercially available, but silicon isn’t as good as perovskite at converting light to electricity.

Adaptation of a back-contacted design to the perovskite solar cell is incredibly difficult as the interdigitated array of electrodes must be delicately structured, which provides a number of major fabrication challenges.

However, the latest research from a team of CSIRO and Monash University researchers, working out of ANFF-Vic’s Melbourne Centre for nanofabrication, has combined the benefits of both device types using a series of photolithography and vacuum deposition processes. The technique enabled an alternative design in which the interlocking array of anodes and cathodes were no longer on the same plane, but still remained on only one side of the perovskite absorber layer.

The result has, for the first time, demonstrated the possibility of constructing a back-contacted PSC. And while efficiencies are lower than what can currently be achieved in conventional silicon-based devices, the new cells have the potential to provide far higher conversion rates once optimised.

Now, the team are working to develop the processes used to make these cells in order to make them suitable for mass production. Once found, scalable, affordable fabrication techniques will bring back-contacted perovskite solar cells into the light, along with all the advantages they offer.

Diamond coating Carbon Fibre

Exploring gold nanowires and nanorods

Professor Wenlong Cheng from Monash University has been exploring unique properties of gold nanomaterials for over 16 years. Two recent projects, conducted at ANFF-Vic’s Melbourne Centre for Nanofabrication (MCN), involved gold nanorods and gold nanowires.

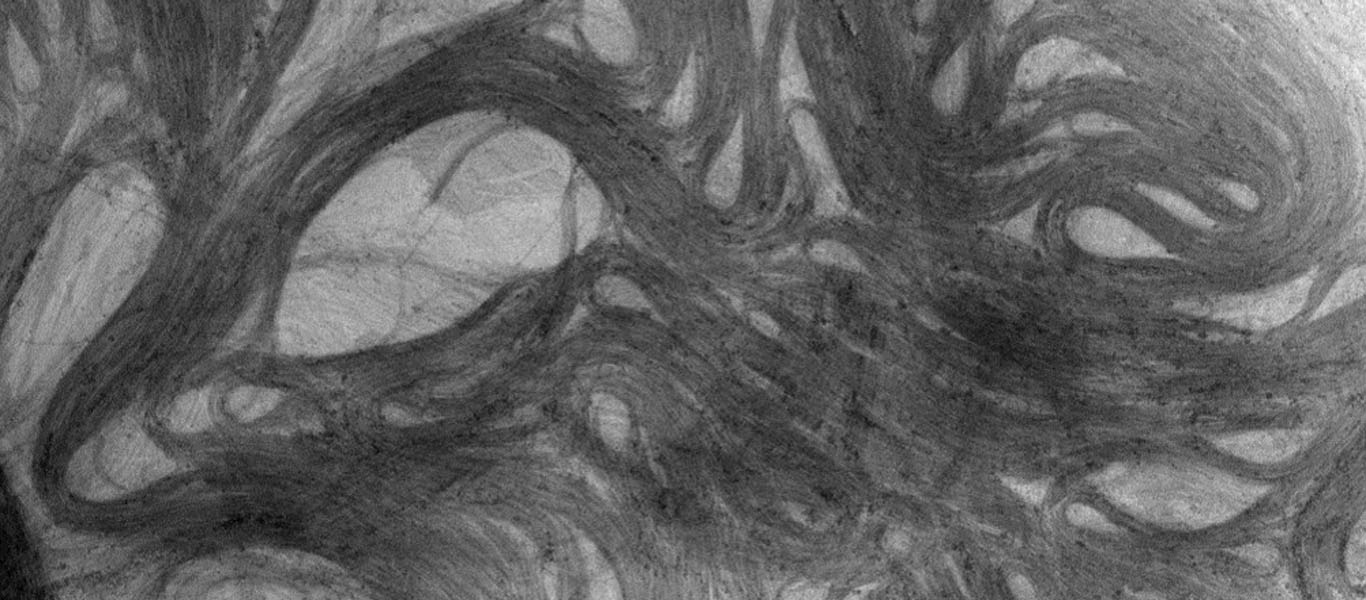

Wearable sensors

Stretchable, conductive materials are driving the capabilities of tomorrow’s soft and wearable technologies.

Wearables may hold the key to accurate and comfortable health monitoring and movement detection. There’s also the potential for a range of intuitive human/machine interfaces to be created that could ultimately enable implantable biomedical devices.

Wenlong and a team of researchers from Monash University have been making a range of flexible sensors by coating elastic materials with interwoven networks of conductive ultra-thin gold nanowires (UGNWs). According to Wenlong, the UGNWs are the world’s thinnest gold nanowires at only 2nm wide — a DNA double helix, by comparison, is just over 2nm in width.

The elastic substrates that the UGNWs are grafted onto are flexible and biologically safe, making them ideal candidates for wearable electronics.

Researchers worked at MCN to create wearable pressure sensors, skin-attachable strain sensors, flexible transparent electrodes and stretchable supercapacitors.

To create a sensor, UGNWs are grown via a solvent-based chemical process that yields a host of hair- like ultra-thin fibres. Once in a liquid suspension, the wires are “painted” onto the elastic material, forming

an interwoven mesh of electrically conductive fibres once the paint dries. When the UGNW-coated elastic

is stretched, the device’s electrical resistance changes too, providing

a real-time and reversible electrical representation of the sensor’s state.

Wenlong exploits these changing properties to detect and monitor movement with an incredibly high degree of precision. His devices offer touch sensitivity and can pick up the tiny forces associated with artery wrist pulses.

“They are able to resolve pressing, stretching, bending, and torsion

forces as well as acoustic vibrations,” Wenlong said. The team’s devices are cheap to manufacture and attachable to almost any surface, allowing accurate measuring of skin or muscle deformation anytime, anywhere.

In the health sector, for example, increased sensitivity of these devices could reveal previously undetected heart defects or be used to monitor detailed hand movements in robotic infrastructure such as advanced prosthetics.

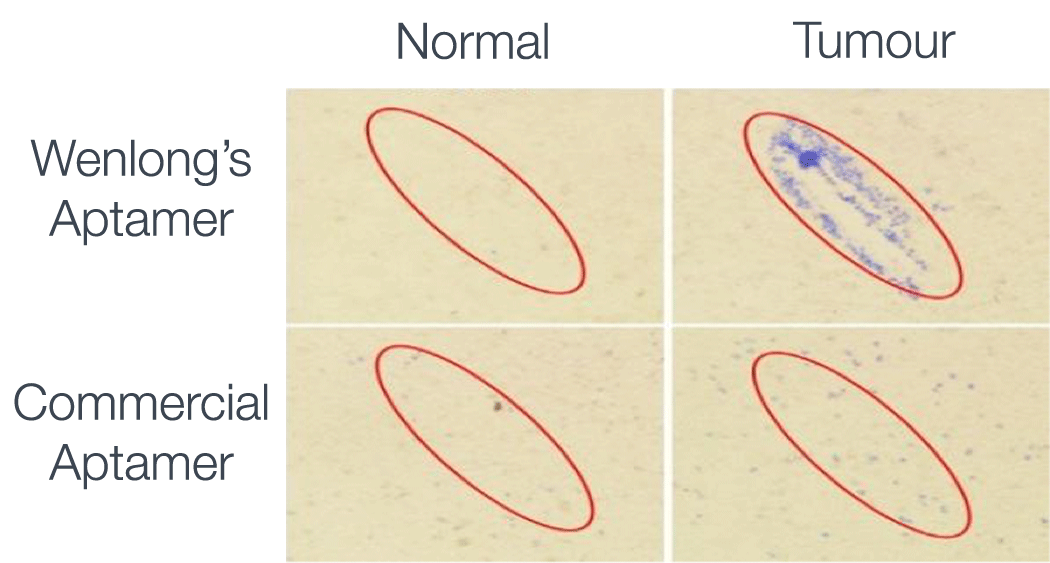

Targeting tumours

At present, the vast majority of cancer treatments work by attacking cancer cells but often affect healthy tissue in the process. The approach, whilst effective, produces a large number of side effects including irreparable and extensive tissue damage, hair loss and nausea, among others.

There has therefore been a great deal of effort devoted to improving the selectivity of cancer therapies in order to minimise collateral damage. Increasingly, the idea is to hunt with a sniper rifle, rather than a shotgun.

Wenlong and his colleagues have gone a step further and developed what is effectively a guided missile that exclusively binds to target tumours before heating defective tissue to the point of destruction. Advancing a treatment called photothermal therapy, the method uses gold nanorods (GNRs) – shorter, wider versions of gold nanowires – which rapidly heat up to 45°C when irradiated by near-infrared (NIR) light.

To specifically target the cancerous cells, the GNRs are coated with DNA-specific aptamers that Wenlong selected to identify DNA unique to

the tumour cells. Aptamers are single strands of DNA that bind selectively

to a complementary piece of genetic material. The theory is that once the aptamer binds to the target tumour cell, the GNR is heated with the NIR light and the cell is destroyed.

Wenlong and his team collaborated with a team led by Professor David Jans, NMHRC Senior Principal Research Fellow at Monash University to test the GNR-aptamer “missile” on breast ductal carcinoma cells residing in healthy tissue.

Wenlong’s team was able to observe the selectiveness and efficacy of this process using the MCN’s hyperspectral imaging capabilities. The initial results indicate that once the GNRs had been heated by NIR light, 96 per cent of tumour cells had been successfully targeted and 71 per cent of them were destroyed, with less than one per cent of healthy tissue affected.