New furnace and optical profilometer

Four stack furnace

To compliment the high temperature furnace facility already available at the MCN, a new four-stack horizontal furnace is currently being installed in the class 10,000 cleanroom. This new furnace will allow batch processing of up to 150mm wafers and will provide access to high temperature processing (>1000 degrees Celsius) of silicon and other substrates. The system features a HEPA controlled loading station as well as four individual processing tubes to cater for dopant diffusion, annealing and the low-pressure chemical vapour deposition of silicon nitride.

This furnace will be available to users in the next few months. Please contact paul.spizzirri@nanomelbourne.com for more information.

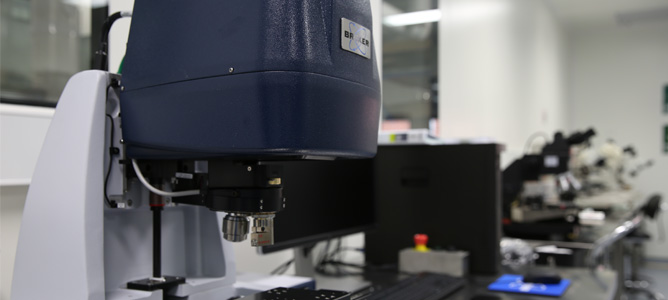

Optical Profilometer

MCN is the first facility in Australia to install an all-new Bruker Contour GT-I Optical Profilometer – a fully automated, desktop optical microscope which measures surface features over a range of angles. The combination of tip/tilt in the head with automated staging and objectives, as well as vibration resistant measurement techniques, make the Contour GT-I ideal for measure on demand industrial requirements.

The Contour GT-I joins MCN’s Ambios XP 200 profilometer and provides a 3D optical profilometry capability. Optical profilometry employs phase-shifting and/or vertical scanning interferometry to resolve the topology of complex 3D structures. The technique marries precision z-axis control with interference based techniques to resolve features from the angstrom to millimetre scale. The technique lends itself well to die-based measurements for ISO/QA and large area mapping.

The optical profilometer will be available to users from August 2014. Please contact sean.langelier@nanomelbourne.com for more information.