ANFF-VIC user awarded Leverhulme Medal 2019

Professor Frank Caruso has been awarded the Leverhulme Medal 2019 by the Royal Society for “driving the application of engineered particles in biology and medicine through nanoscale materials engineering.”

Professor Frank Caruso has been awarded the Leverhulme Medal 2019 by the Royal Society for “driving the application of engineered particles in biology and medicine through nanoscale materials engineering.”

The Leverhulme Medal is awarded for an outstanding researcher in the field of chemical engineering and applied chemistry.

Professor Caruso is a prominent user of ANFF-VIC’s capabilities at the University of Melbourne, and ANFF-VIC would like to congratulate him on this recognition of his continuing outstanding materials research.

Farewell to MCN’s Operations and EHS Manager

Paul Spizzirri has decided to move on to his next chapter and will be leaving his position as Operations and EHS Manager at the Melbourne Centre for Nanofabrication (MCN) after more than eight years in the role.

Paul joined the MCN in May 2011, bringing with him over 20 years of extensive laboratory experience with the last 13 years focused on silicon processing technologies applied to the fabrication of a solid-state quantum computer.

As a farewell message, Paul said: “MCN and the ANFF-VIC Node have been amazing environments to work in. The people, technology, and opportunities have been life changing and I’ve enjoyed my journey immensely. It has truely been a privilege to with this team who I know will go on to deliver amazing outcomes for Australia and the ANFF community.”

Paul has done a truly outstanding job managing the operation of central infrastructure and equipment that supports MCN’s state-of-the-art laboratory facilities, helping to grow the MCN’s capability portfolio, user base, and its reputation.

Messages from the network:

Commenting on Paul’s fantastic career at MCN, Professor Nico Voelcker, MCN/ANFF-VIC Director, said: “Paul has been an extraordinary leader and will definitely be missed. The systems and processes Paul has developed and implemented have allowed the MCN to operate at the highest level, and it’s done so safely. On behalf of everyone at MCN, I would like to thank Paul for his many contributions over the years and wish him the best of success in future challenges and endeavours.”

Dr Jane Fitzpatrick, ANFF Chief Operating Officer, stated: “Paul has provided an amazing level of value to both ANFF-Vic and the whole ANFF network throughout his time at MCN. His skills, knowledge and demeanour have earned him the greatest levels of respect and friendship across our organisation. Although ANFF will be sorely disappointed to see him leave, we wish him all the best in his coming endeavours.”

Dr Cathy Foley, CSIRO Chief Scientist, said: “Paul, thank you for all your work and inspiration for the ANFF Vic Node. You have been instrumental in creating a world-class facility that has an incredible impact on Australian research that is enduring. You leave an amazing legacy that you should be very proud of, and good luck for your future endeavours.”

Professor Ian Smith, Monash University Vice-Provost (Research and Research Infrastructure) said: “While I am sorry to hear you are leaving us, I wish you all the best for the next steps. In addition to those that have gained from your endeavours at MCN, Monash University has also benefited enormously from your leadership, selfless contributions and drive to ensure we are all working in an as healthy and as safe environment as possible, so thank you.”

PhD Student’s work highlighted in Advanced Healthcare Materials

Daniela Duc has had her work, which was performed in part at the ANFF-Vic Biointerface Engineering Hub at Swinburne University of Technology, highlighted on the inside cover of Advanced Healthcare Materials. The publication is entitled Electrical Cell Stimulation: Fabrication of a Biocompatible Liquid Crystal Graphene Oxide–Gold Nanorods Electro‐ and Photoactive Interface for Cell Stimulation.

This work outlines the deposition of graphene oxide/gold nanorod composite surfaces for the growth of neuronal cells and utilized the air plasma reactor at the ANFF-Vic Biointerface Engineering Hub to make the substrates more hydrophilic prior to the graphene oxide coatings.

Daniela is a PhD student at Swinburne University of Technology working as part of the ARC Centre of Excellence for Electromaterials Science. This paper is the first from Daniela’s PhD. Daniela has also received a commendation for this article in Swinburne’s 2019 Faculty of Science Engineering and Technology – Higher degree by research awards.

Link: https://onlinelibrary.wiley.com/doi/10.1002/adhm.201801321

Probing in vitro cells

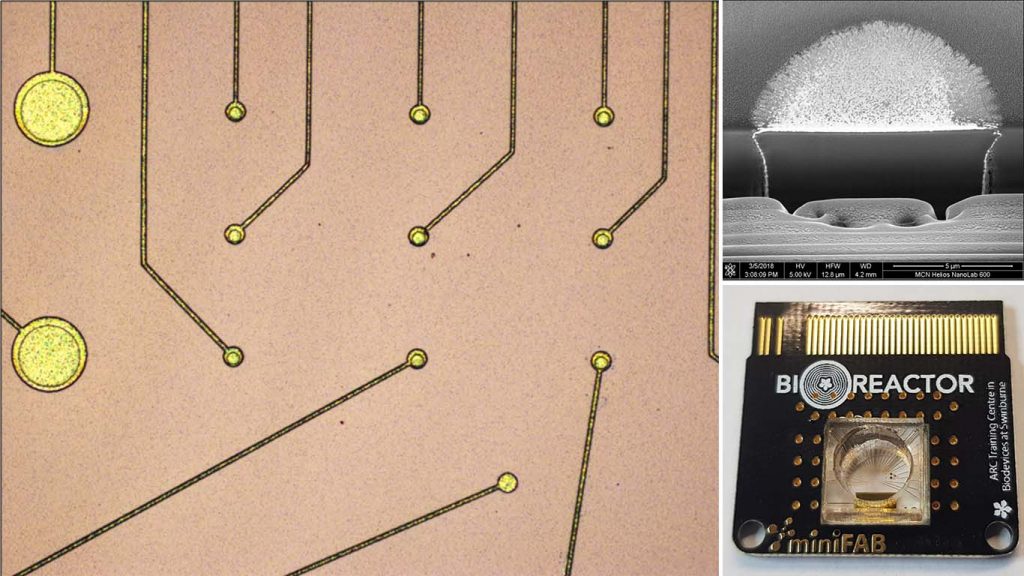

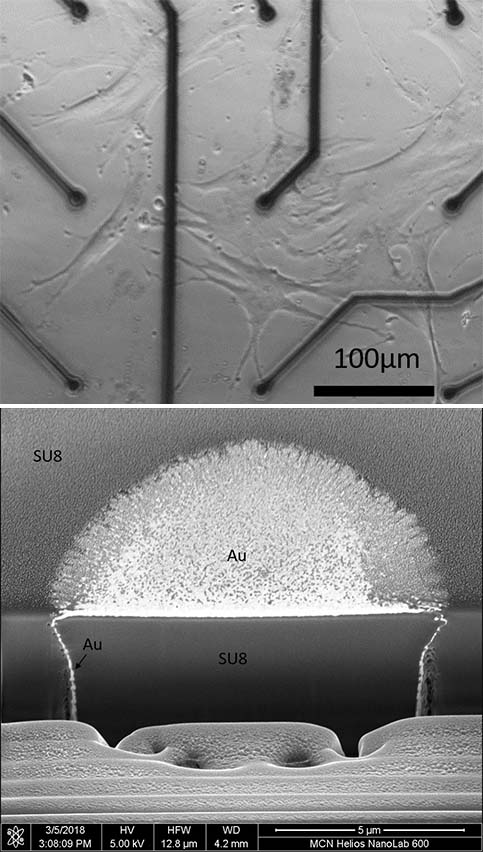

Scientists from the ARC Training Centre in Biodevices at Swinburne University developed a microscale multi-electrode array device (MEA) as a tool that probes the electrical properties of adherent single cells to identify their biological characteristics.

Monitoring cellular parameters in vitro is a fundamental requirement at the core of cell biology and impacts all the medical field and beyond. This technology was investigated for its potential to be used to test cell characteristics produced for cell-based therapies and reduce the cost related to their production.

The research project was conducted by Dr Steve Beguin under the supervision of Prof. Sally McArthur and in collaboration with industry partner MiniFAB. The facilities at the Melbourne Centre for Nanofabrication were extensively used by the researchers to develop a new method to manufacture microscopic electrodes that enabled high resolution and high-quality measurement of single cells in a culture of human stem cells.

The exceptionally flat topography of the microelectrodes allowed the tight cell-substrate sealing necessary to perform the measurements, which outperformed previously reported sealing resistance by 10 – 1,000-fold and allowed to directly measure the specific capacitance of the cell plasma membrane.

The project was one of the 10 PhD in Technology Innovation completed with industry in the ARC Training Centre in Biodevices at Swinburne.

Image captions

Header image – Left: Top view of MEA electrode array. Top Right: Cross section of device made using FIB-SEM. Bottom Right: The MEA Device.

Inset image – Top: Labelled cross section, made using FIB-SEM. Bottom: Human stem cells on MEA Device.

ANFF CEO appointed

Dr Ian Griffiths has been appointed as the Chief Executive Officer of the Australian National Fabrication Facility (ANFF), commencing this quarter. The decision was announced by ANFF’s Chairman and Board on 8 July 2019, following an extensive four-month search.

Dr Ian Griffiths has been appointed as the Chief Executive Officer of the Australian National Fabrication Facility (ANFF), commencing this quarter. The decision was announced by ANFF’s Chairman and Board on 8 July 2019, following an extensive four-month search.

Dr Griffiths is currently CEO of Wound Innovations Pty Ltd, a spin-out from the Wound Management Innovation Cooperative Research Centre of which he was Director and CEO. Over an extensive career in Australia and the UK he has successfully established companies based on new technologies and worked with universities, industry and government in fostering high-end research and innovation.

As CEO of ANFF, Dr Griffiths will provide leadership and oversight to the eight ANFF nodes that are spread across Australia. Based primarily in Brisbane, QLD, Dr Griffiths will work with the ANFF team to ensure that ANFF and the 500+ micro and nanofabrication capabilities in its open access portfolio continue to enable ground-breaking research.

Publication of the year announced

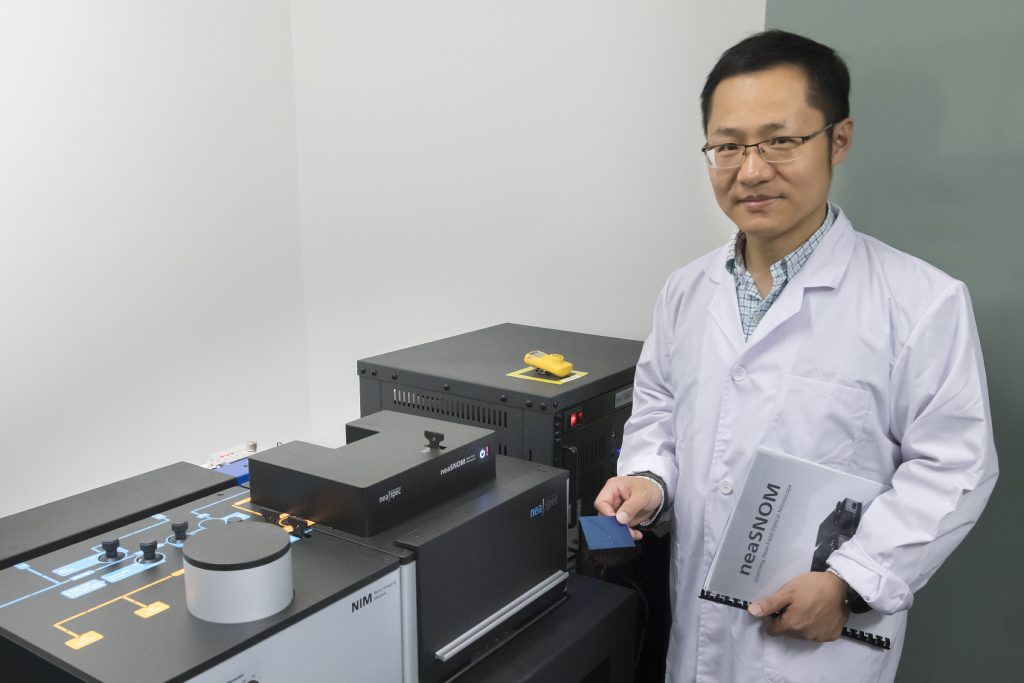

MCN-enabled research published by Professor Qiaoliang Bao and colleagues at the ARC Centre of Excellence in Future Low-Energy Electronics Technologies (FLEET) has been selected as the ANFF-VIC Publication of the Year, following an internal selection process.

MCN-enabled research published by Professor Qiaoliang Bao and colleagues at the ARC Centre of Excellence in Future Low-Energy Electronics Technologies (FLEET) has been selected as the ANFF-VIC Publication of the Year, following an internal selection process.

The team has, for the first time, demonstrated a bizarre behaviour of light that could enable ultra-efficient optoelectrical devices and superfast transmission of information.

The team were working with van der Walls (vdW) materials – a class of materials that feature many weakly-bound layers of atoms – and a hybrid particle called a polariton – a particle of light (a photon) which is bound to a particle of vibrational energy (a phonon).

The paper, In-plane anisotropic and ultra-low-loss polaritons in a natural van der Waals crystal, was chosen as the winner by ANFF-VIC’s selection panel due to its impact, pioneering nature and level of engagement with MCN. All papers that were published in 2018 that correctly acknowledged ANFF-VIC were eligible for selection.

For more information on the project, visit FLEET’s website.

Tickets on sale for ANFF-VIC Winter Workshop

Tickets are now on sale for ANFF-VIC’s Winter Workshop, a two-day event featuring technical talks and practicals aimed at researchers that are new to nanofab or the ANFF network. The Workshop is being held at MCN on 19 and 20 August 2019.

Hear from experts and ANFF-VIC users as they discuss the open-access nanofabrication capabilities made available by ANFF-VIC.

Each day, the mornings will be filled with ANFF-VIC hub-focused talks, presenting 7 locations’ flagship capabilities, example case studies and technical process talks. The afternoons comprise in-lab practicals, demonstrations, and tours of local facilities.

Click here for more information or click here to view the program flyer.

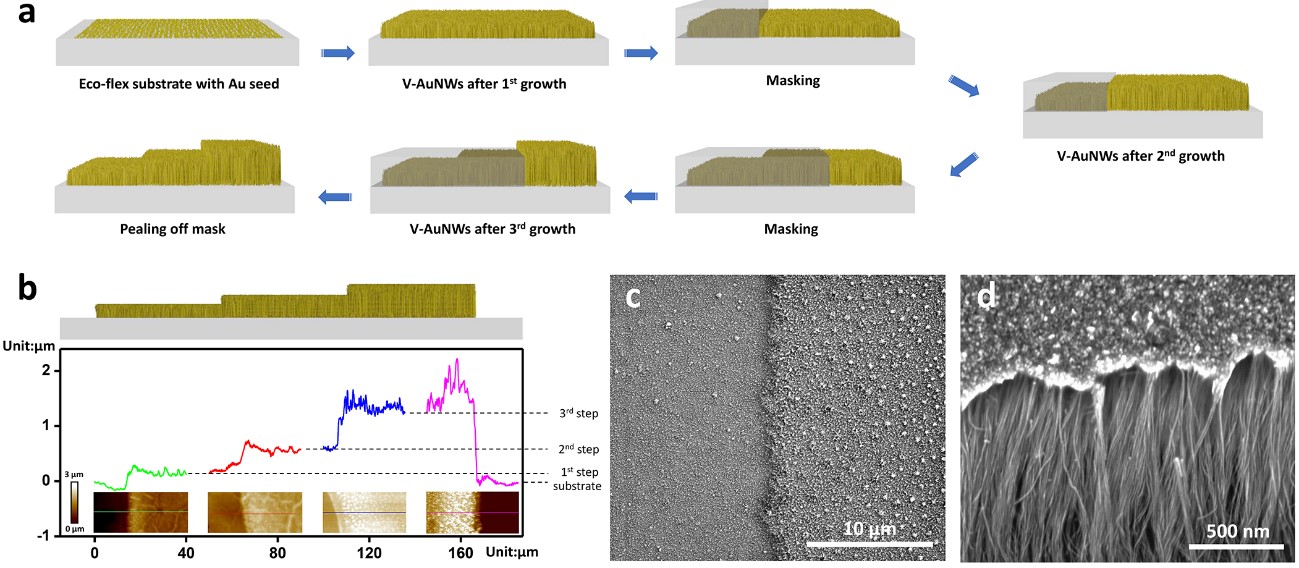

Nanoscale Horizons Outstanding Paper runner-up 2018 enabled by MCN

A paper by MCN resident users has been selected as the Nanoscale Horizons Outstanding Paper 2018 runner-up.

The paper, A location- and sharpness-specific tactile electronic skin based on staircase-like nanowire patches (DOI: 10.1039/C8NH00125A) was written by Shu Gong, Yan Wang, Lim Wei Yap, Yunzhi Ling, Yunmeng Zhao, Dashen Dong, Qianqian Shi, Yiyi Liu, Hemayet Uddin and ANFF-VIC Technology Ambassador, Wenlong Cheng.

According to the RSC, “The article reports on a tactile electronic skin sensor based on staircase-like vertically aligned gold nanowires. With a back-to-back linear or spiral assembly of two staircase structures into a single sensor, the authors were able to recognize pressure in a highly location-specific manner for both non-stretched and stretched states opening up a new route to highly specific second-skin-like tactile sensors for wearable sensing applications.”

Nanoscale Horizons, a journal published by the UK’s Royal Society of Chemistry, put together a shortlist of articles published during 2018 based on the science presented and the article metrics including average article downloads and citations, and Altmetrics. The shortlist was reviewed by the journal’s Editorial and Advisory Board members.

Platform Manager Position Available At UniMelb

There is currently a Platform Manager position available at the University of Melbourne to lead the operations of the Materials Characterisation and Fabrication Platform (MCFP) at the Department of Chemical Engineering. This position is a maternity leave backfill for a period of 9 months.

The deadline for applicants is 1 May 2019, click here for more details.

ANFF-VIC Technology Ambassadors – Class of 2019

ANFF-VIC has welcomed three new Technology Ambassadors in March – Dr David Garrett, Dr Ranjith Unnithan and Professor Peter Kingshott.

Since the TA scheme was initiated in 2011, Ambassadors have been selected from a broad range of disciplines, each with their own unique demands for micro/nanotechnology.

In addition to their core research activities, ANFF-VIC TAs use their considerable expertise to create new processes that benefit the ANFF-VIC user community and undergo in-kind cooperative activities reflecting the current and emerging needs of researchers in their respective fields.

There is now a total 12 ANFF-VIC Technology Ambassadors: Saulius Juodkazis (Swinburne), Qialiang Bao (Monash), Victor Cadarso (Monash), Ranjith Unnithan (UniMelb), Sharath Sriram (RMIT), Grant van Riessen (La Trobe), David Garrett (UniMelb), Anthony Chesman (CSIRO), Peter Kingshott (Swinburne), Udo Bach (Monash), Wenlong Cheng (Monash), Lingxue Kong (Deakin)

Dr David J. Garrett

Senior Research Fellow – University of Melbourne

Dr David Garrett’s career has been aimed at overcoming the limitations of neural interface technology using carbon materials, resulting in a series of patents and more than 40 papers within eight years.

In 2015, Dr Garrett founded a start-up in Canada, based around commercialising a retinal prosthesis developed in his early career.

Dr Garrett will be focused on how to translate devices that harness the properties of nanometre-thick layers of diamond to industrially relevant applications, investigating both the abilities of these devices, and the way they connect with the outside world.

As such the team will be heavily using MCN’s diamond deposition suite, featuring two Seki MPCVD systems that are used for growing ultra-high purity and nitrogen vacancy diamond, or for growing boron-doped diamond.

Dr Ranjith Unnithan

Senior Lecturer – University of Melbourne

Dr Ranjith Unnithan’s research areas span CMOS image sensors, electronic sensors for biomedical applications, thermal image cameras and nanophotonic engineering.

In addition to publishing a string of high-impact papers, Dr Unnithan has demonstrated a talent for commercialising technologies, having won four innovation awards and co-founding Hort-Eye Pty Ltd – a precision drone sensing company – with a team from the University of Melbourne.

Dr Unnithan will be working to improve the ways in which nanostructures are incorporated with electrical devices such as CMOS image sensors. He aims to improve the fabrication process of these nanostructures to allow them to be created directly onto a sensor, which would reduce the size, weight and power consumption of these devices compared to traditional technologies.

Nanostructures are of interest to imaging applications as they can be used to tune a sensor to particular bands of the light spectrum, making them incredibly useful when trying to collect as much information about a field-of-view as possible. However, current methods to create the structures involve the use of heat, vacuums or plasmas which can reduce the sensitivity of the sensor instead of enhancing it – fabrication issues Dr Unnithan hopes to overcome using novel manufacturing processes.

Dr Unnithan’s project will be reliant on MCN’s high-resolution lithography systems, including the NanoFrazor which uses a heated cantilever tip to create structures with a resolution of ~10nm.

Professor Peter Kingshott

Department Research Director – Swinburne University of Technology

Professor Peter Kingshott has built an international profile in the multidisciplinary field of biointerface science – his expertise extends into nanomaterials, colloid and surface science, biomaterials, biomedical engineering, and regenerative medicine.

He has published more than 150 publications, holds a range of patents, and has been the editor for Applied Surface Science for more than five years.

Professor Kingshott and his researchers will be investigating advanced surface nanostructures for biomedical applications with a particular focus on the ways surface topography can encourage or manipulate stem cell growth.

This broad-scoped project will also delve into surface chemistries and patterns that could inhibit the growth or movement of bacteria.

Professor Kingshott will be using a range of both masked and maskless lithography techniques – in addition to characterisation, plasma polymerisation, and atomic layer deposition capabilities – from across the hubs of ANFF-VIC as he conducts his research.