Results of 2016 User Satisfaction Survey

At the end of 2016, MCN conducted its annual User Satisfaction Survey to ensure that the centre is performing to its users’ expectations.

The results show that MCN continues to deliver a high-quality service according to the user cohort, averaging scores of more than 4.2 out of 5 in all key areas including timeliness for tool access, consulting expertise, operating performance, staff communication, and waiting period for training.

The report also showed that the number of tools used on a per user basis grew from 2015, indicating that users are making use of an increasingly diverse tool set. It was particularly encouraging to see the strong usage of new tools that the centre has brought in.

Feedback highlighted a range of “wish-list” tools and capabilities that were in demand, all of which are now being investigated.

MCN would like to thank all participants of the survey and hopes that all users will be adding their input to the 2017 survey which will be organised at the end of the year.

Recent publications

Here’s a collection of the recently published papers that have made use of ANFF-VIC’s open access facilities. To see more of the latest ANFF-enabled research, head to our publications page.

| Title | Journal | Authors |

| A microfluidic system for studying particle deposition during ultrafiltration | Journal of Membrane Science | H. Di, G. Martin and D. Dunstan |

| Energetic deposition, measurement and simulation of graphitic contacts to 6H-SiC | Microelectronics Reliability | H. Tran, M. Kracica, D. McCulloch, E. Mayes, A. Holland and J. Partridge |

| A Green Route to Conjugated Polyelectrolyte Interlayers for High-Performance Solar Cells | Angewandte Chemie | J. Subbiah, V. Mitchell, N. Hui, D. Jones and W. Wong |

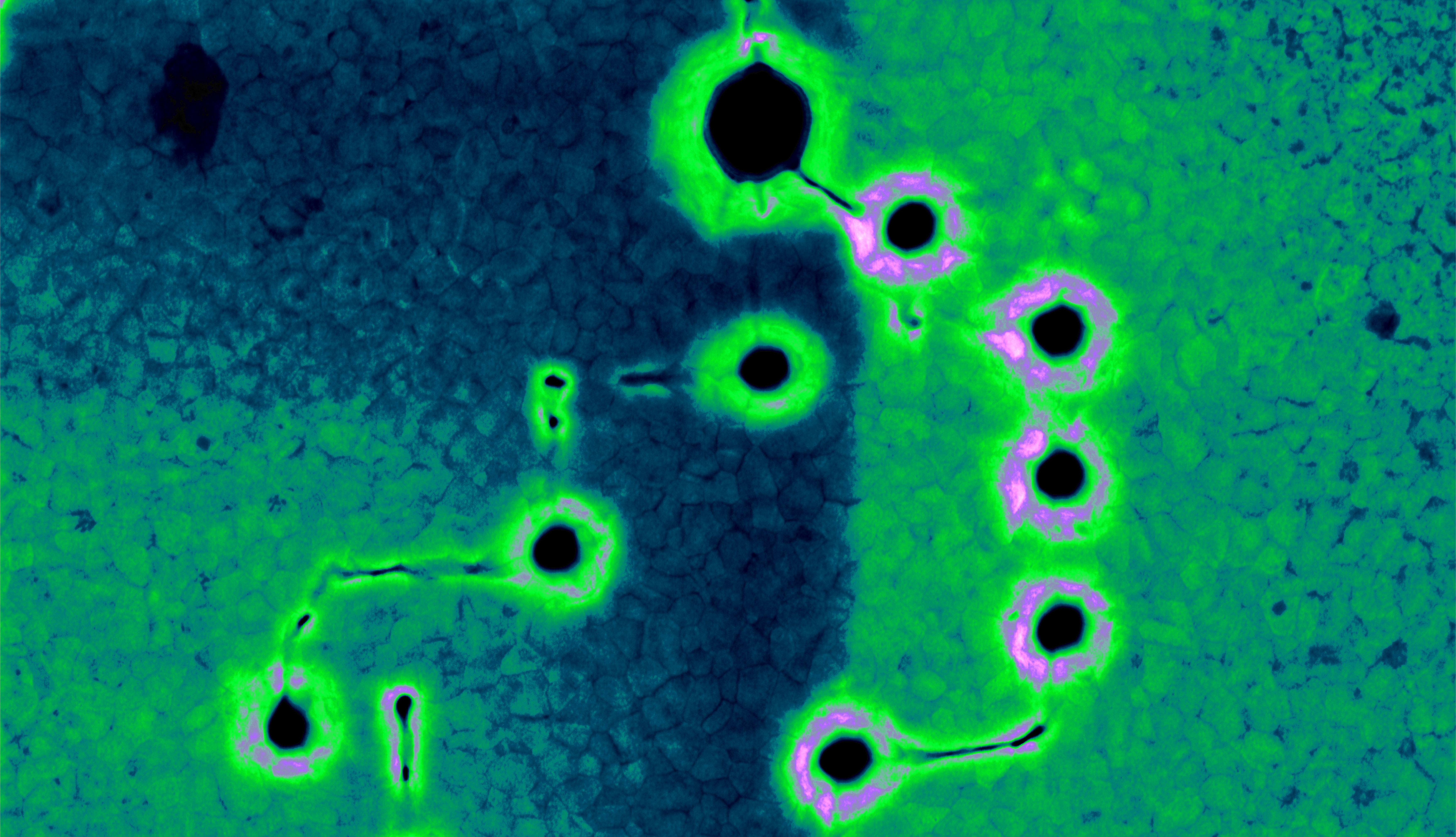

| Revealing the sequence of interactions of PuroA peptide with Candida albicans cells by live-cell imaging | Scientific Reports | N. Shagaghi, M. Bhave, E. Palombo and A. Clayton |

Welcoming the new ANFF-VIC Marketing Officer

On behalf of the Victorian Node of the Australian National Fabrication Facility (ANFF-VIC), MCN is pleased to welcome Tom Eddershaw as the new Marketing and Communications Officer for ANFF-VIC and ANFF.

Tom’s duties will see him heavily interacting with staff and users, promoting the hard-earned fruits of their labour. By creating a range of print and web-based content, Tom will tell the stories of ANFF users and staff, while making sure knowledge of the ANFF network’s capabilities is spread to all researchers.

As MCN offers a perfect location for guest seminars and talks, the Tom will be aiming to increase the amount of these events and helping users organise events of their own.

Tom has a background in science journalism and is very keen to assist users with writing media-ready material and taking/preparing images to accompany this content. He will also being available to offer advice about writing for press, prepping for interviews and science communication in general.

If you have any questions, want to arrange a meeting or just want to say “Hi”, talk to Tom.

Sale pricing extended to July

MCN is continuing its sale prices until the end of July, offering reductions to tool usage and staff assistance.

The sale prices are:

- 25% off all instrument bookings and caps*

- 20% off staff rates*

* (i) discount may be applied on top of existing block discounts, (ii) discount can not be used for block/prepaid usage outside of sale period, (iii) discount does not apply to the cost of consumables.

Information on MCN’s Pricing Policy can be found here. If you have any questions regarding the discounted pricing schedule, please contact us.

Upcoming training and events

In March and April, MCN will be hosting a number of training courses in the MCN boardroom. These sessions are of critical importance to the safety and progression of the Centre’s users, so please save the dates. You don’t need to book for any of the training events unless you intend to bring a large group.

Induction refreshers

Abridged refresher courses are compulsory for all users of the MCN facility and must be completed every 12 months to maintain access. These are held biannually in April and October and last for approximately one hour each. Attendees are asked to bring their access fobs for renewal.

Upcoming dates: Monday 10 April, 2-3pm, Tuesday 11 April, 10-11am, Wednesday 12 April, 2-3pm, and Thursday 13 April, 10-11am.

Occupational Health & Safety Training

OH&S training is available to all users.

Upcoming dates:

Day 1: Wednesday 15 March 9.30am – 5.00pm covering essential OH&S, risk management, and workplace safety inspections.

Day 2: Thursday 16 March – 9.30am – 4.30pm covering ergonomics and manual handling, hazard and incident investigation, hazardous substances and dangerous goods awareness.

Cancelled Induction Training

The General Induction & Dangerous Goods Waste Management Induction scheduled for Monday 17 April have been cancelled due to the Easter public holiday.

The next general induction will be held on 1 May.

And the winner is…

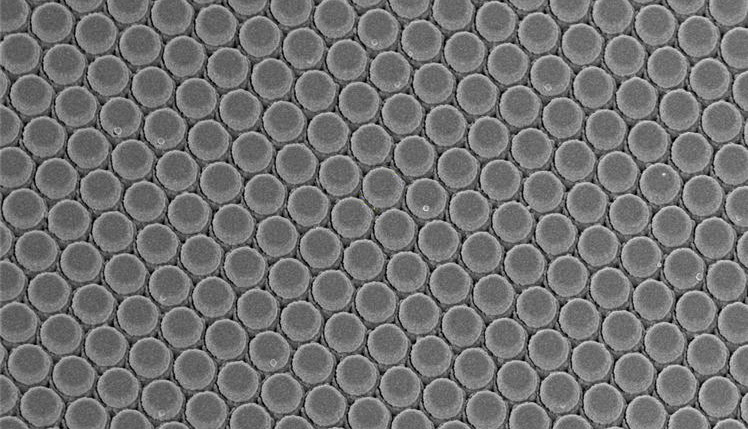

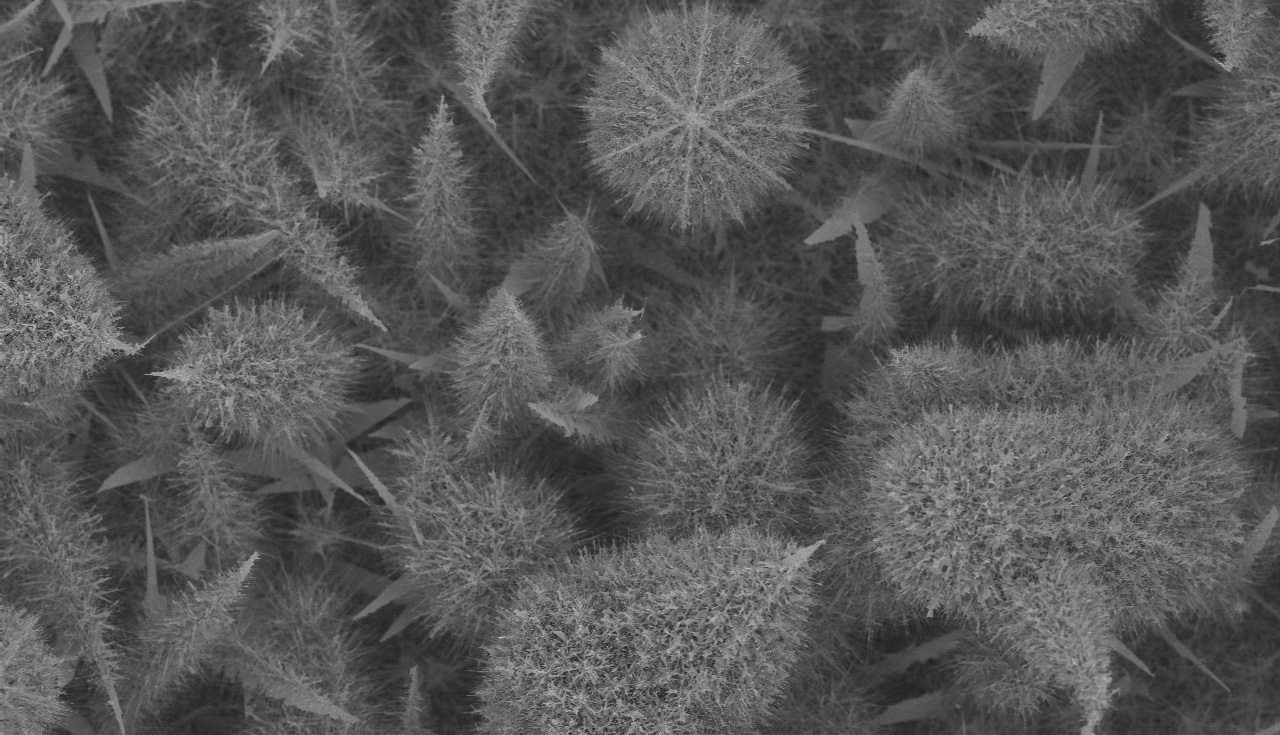

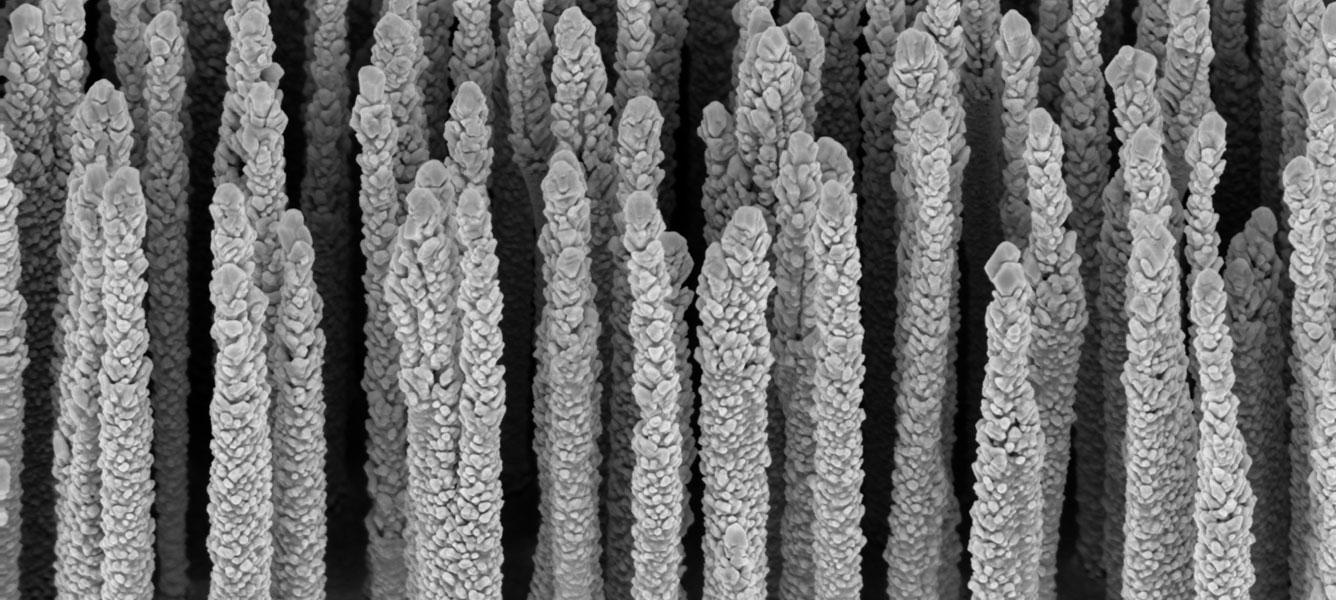

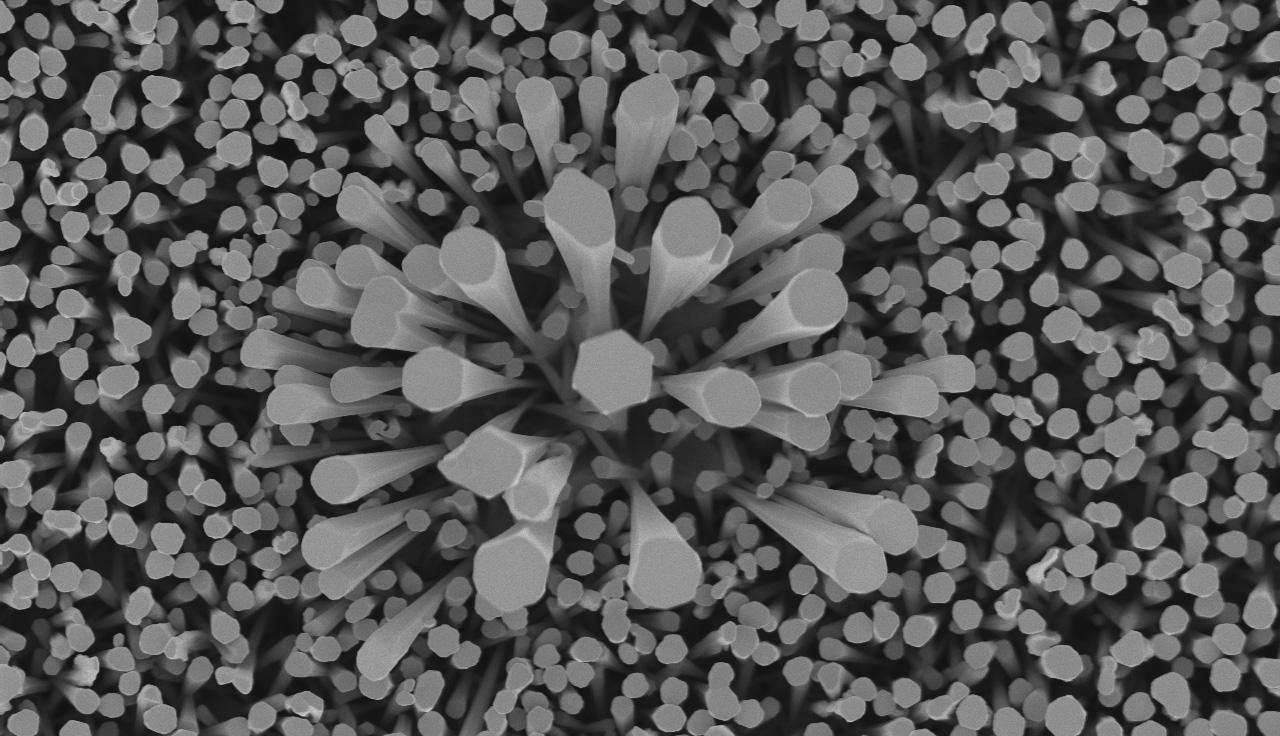

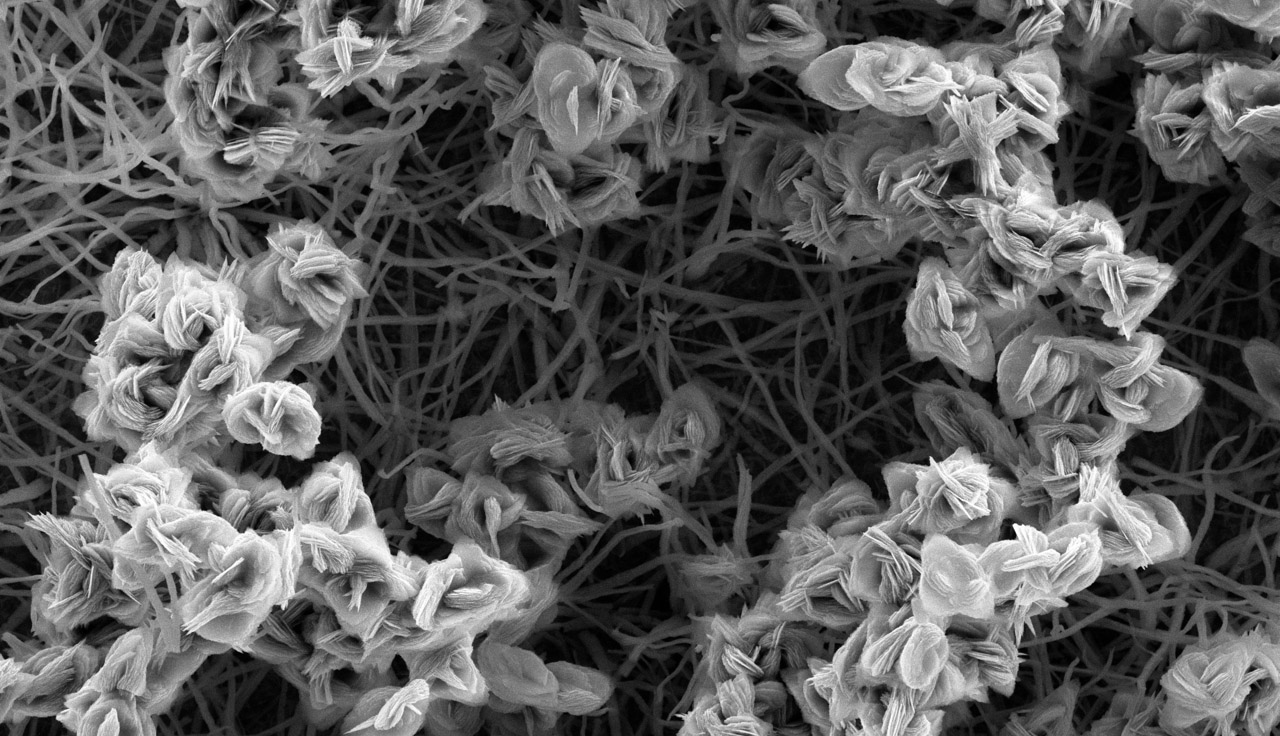

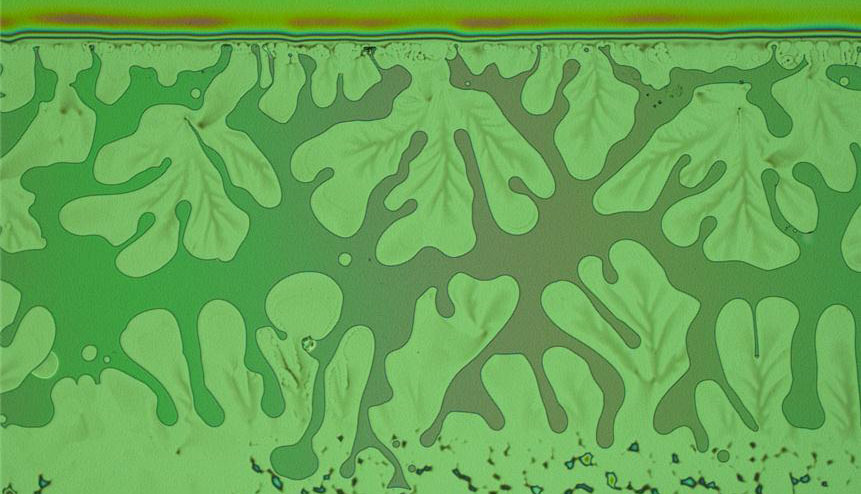

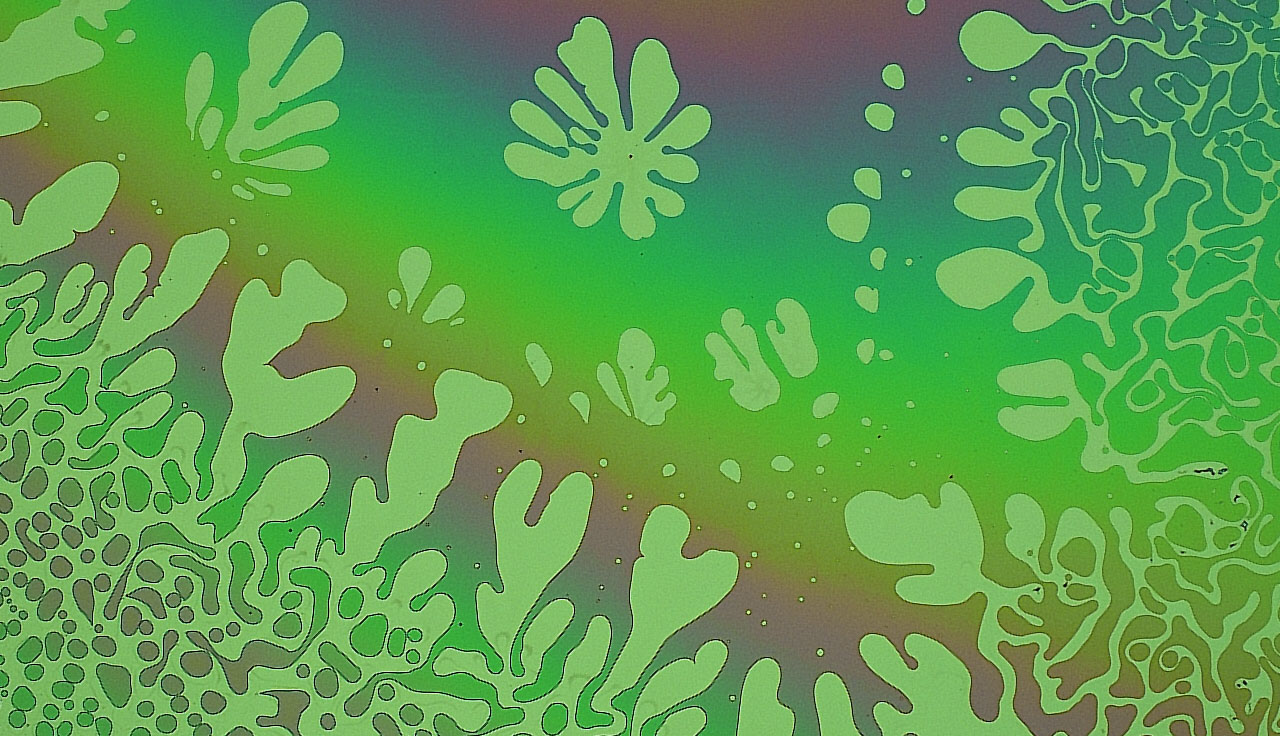

The votes are in, the ANFF-VIC Image of the Year Competition has been won by Dr Tridib Saha for his submission, “Rebel”, following a public vote on our twitter page.

Tridib’s work on improving the efficiency of ultraviolet (UV) sensors produced the image, demonstrating that nanofabrication is not only important, but also easy on the eye.

Tridib’s research required the creation of zinc oxide nanostructures on a piezoelectric crystal, langasite. The result is a ZnO-based thickness shear mode resonator that has demonstrated exciting benefits over predecessor technologies. The device, once refined, could potentially be used to generate low-power UV sensors, and therefore as energy-efficient alternatives for a feast of remote sensing applications.

Tridib’s work was conducted at Monash University Malaysia and characterised in part at the Melbourne Centre for Nanofabrication (MCN). MCN’s laser Doppler vibrometry equipment was used to take non-contact measurements of the surface of Tridib’s ZnO sensor.

ANFF-VIC would like to thank all of this year’s competitors and all of those who voted. The full submissions list is linked below and make sure you enter next year’s competition.

Swinburne researcher awarded Victorian Fellowship

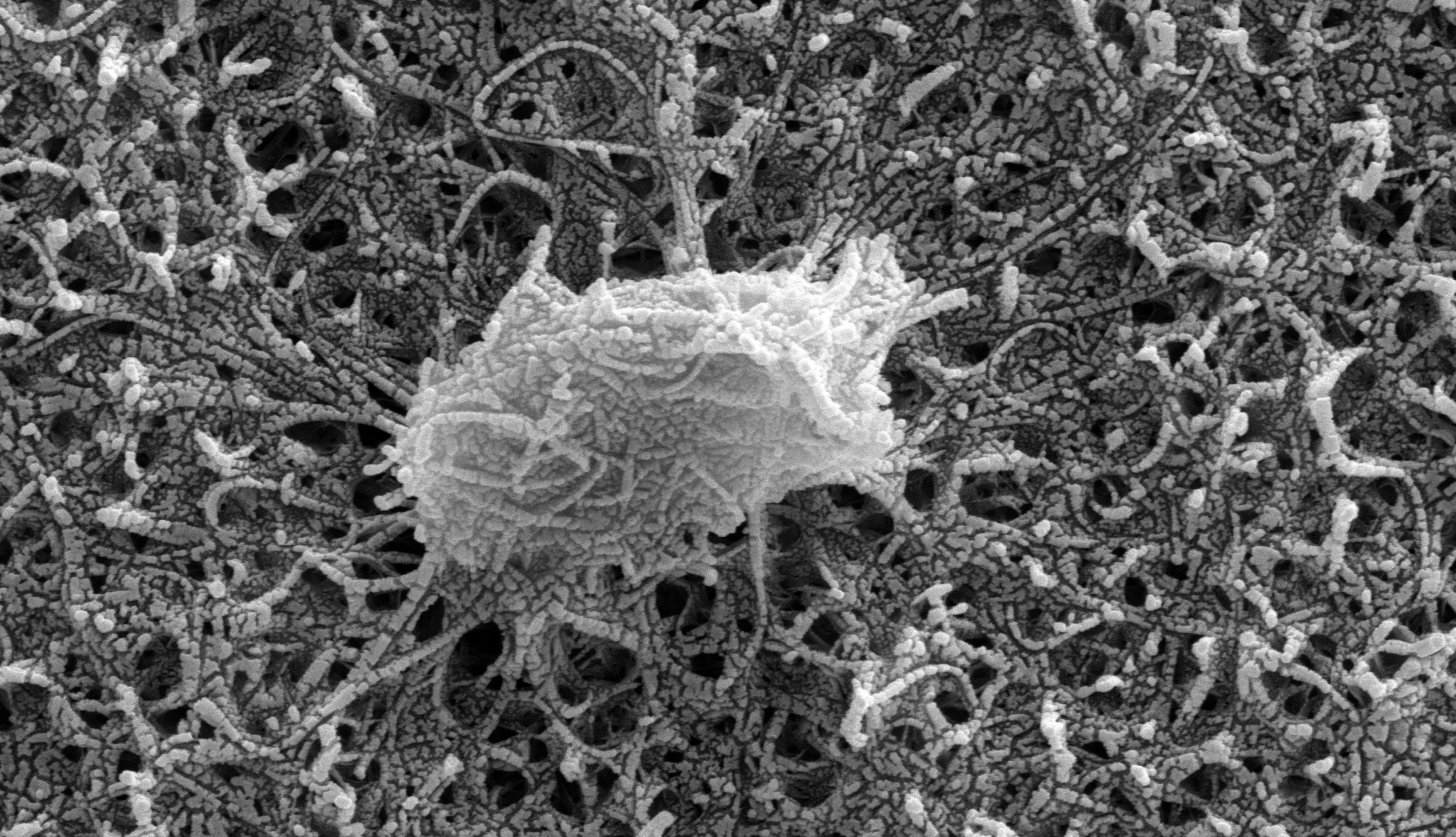

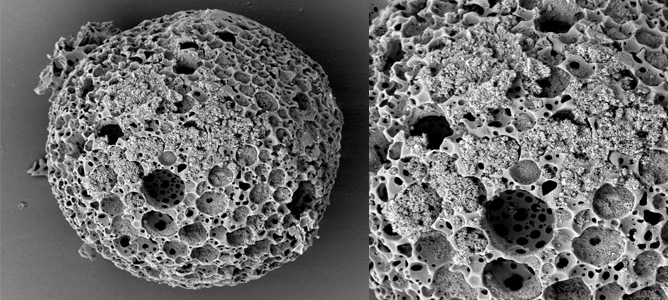

Dr Peng-Yuan (George) Wang has been awarded a Victoria Fellowship to assist with an international study mission.

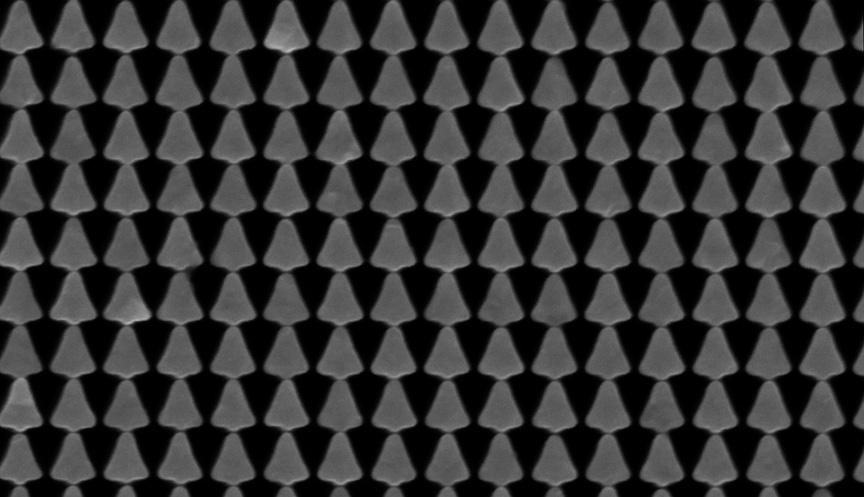

George, who is an ARC Discovery Early Career Researcher Award Fellow at Swinburne, has been studying stem cells, nanofabrication, and advanced materials for more than a decade, researching how surface properties influence stem cell behaviour.

He has been making use of the UV/Ozone cleaner and a plasma reactor at the ANFF-Vic Biointerface Engineering Hub based at Swinburne to clean and pretreat surfaces, as well as the Melbourne Centre for Nanofabrication’s atomic force microscopy (AFM), Reactive Ion Etching (RIE) and confocal microscopy capabilities.

George is one of 12 early career researchers to be awarded the Victoria Fellowship by the Victorian Government valued at up to $18,000. He will visit two world-leading labs in stem cell research and bioengineering in the USA and Canada.

For more details head to the Swinburne website.

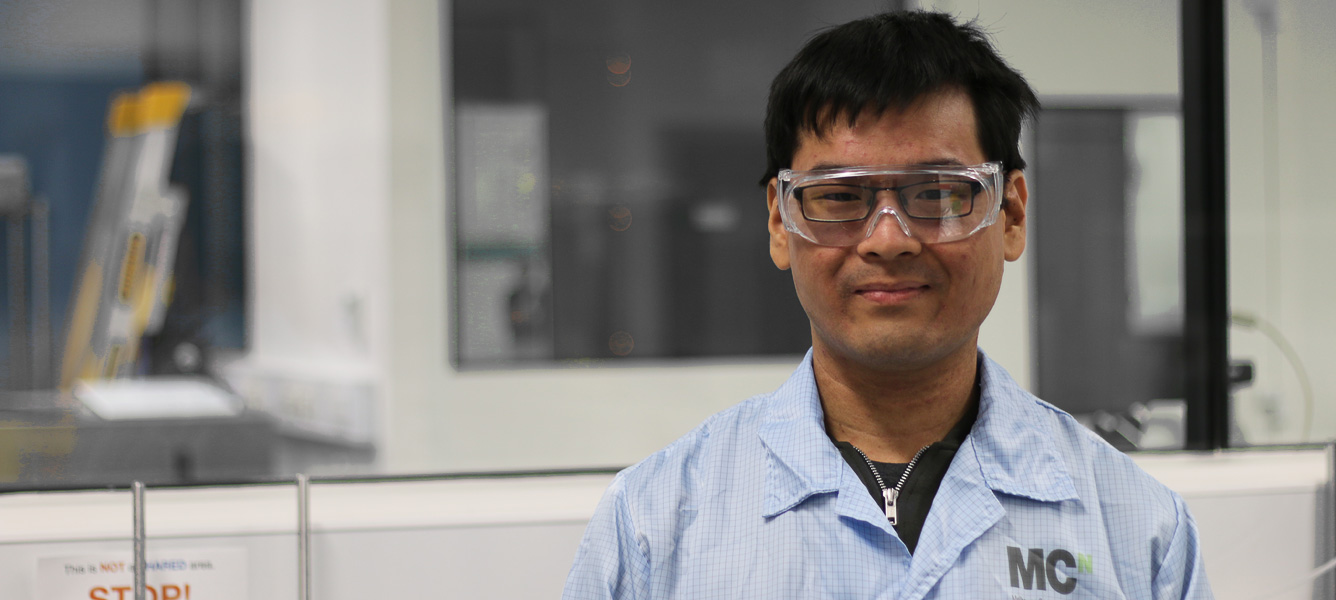

Congratulations Dr Soon Hock Ng

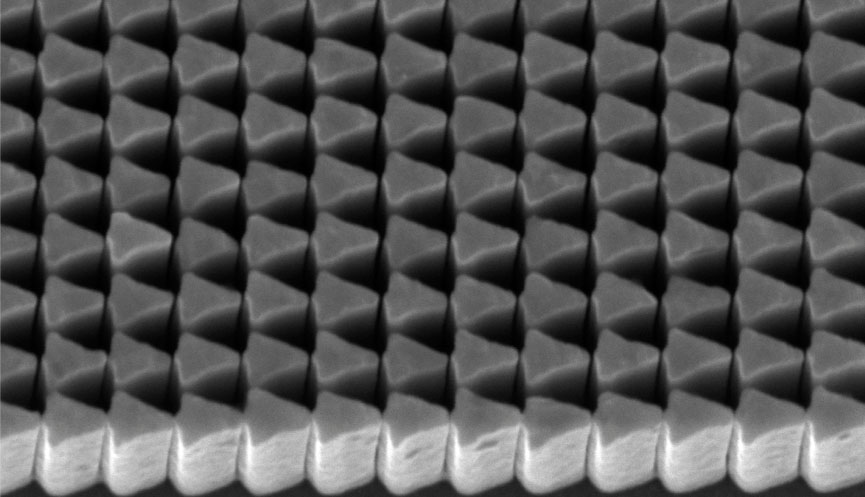

MCN would like to congratulate Dr Soon Hock Ng on the successful completion of his PhD. Soon Hock started his doctorate with Monash University in 2012, when he began investigating self-assembling nanoparticle structures.

Soon Hock is now a Process Engineer at MCN where he makes use of the expertise he gained during both his doctorate and earlier studies.

Congratulations Soon Hock and continue the good work!

MCN staff recognised with Frater Awards

Two of MCN’s staff were recognised with Frater Awards at this year’s ANFF Annual Research Showcase, held 15-17 November 2016.

Named after ANFF’s first chairman, Dr Robert Frater AO (pictured far right), Frater Awards are a professional development award given to ANFF staff for outstanding achievement. The award funds local or international travel aimed at fostering technical and professional growth.

MCN staff recognised were Dr Yang Lim (pictured centre left) and Dr Hemayet Uddin (pictured centre right).

Yang is heading to Canada to train with experts in Intlvac Thin Film Corp extensive development laboratory increase her knowledge of advanced electron beam evaporation techniques.

Hemayet will use the opportunity to travel to Switzerland for on-site training at SwissLitho, IBM and ETH to strengthen his expertise in Thermal Scanning Probe Lithography (t-SPL) and related supporting processes.

MCN would like to congratulate both Yang and Hemayet, as well as the other award winners, Dr Li Li (ANFF-ACT), Dr Wael Al Abdulla (ANFF-Q), and Dr Donghoon Chang (ANFF-SA).

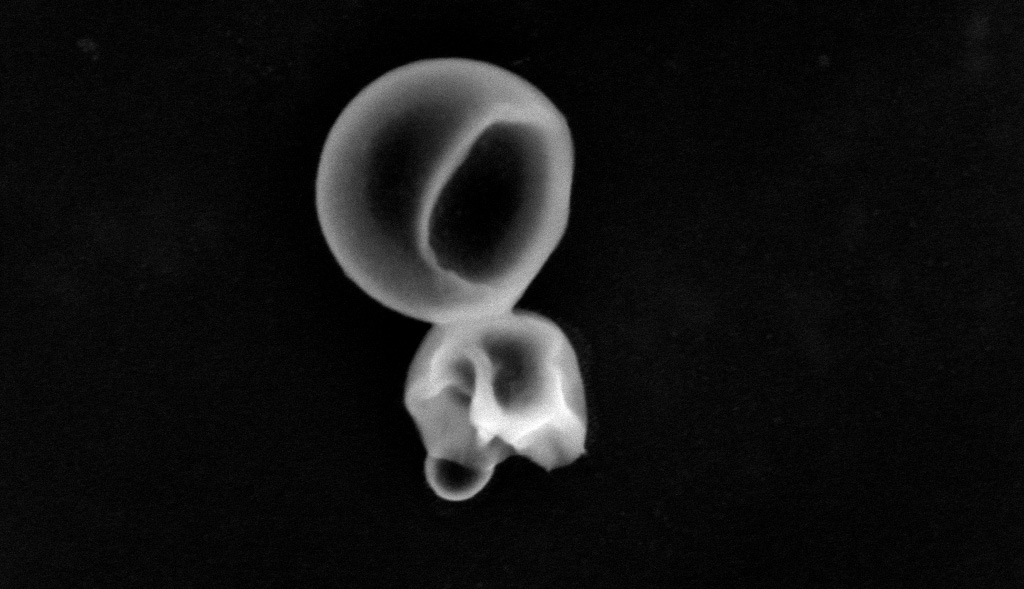

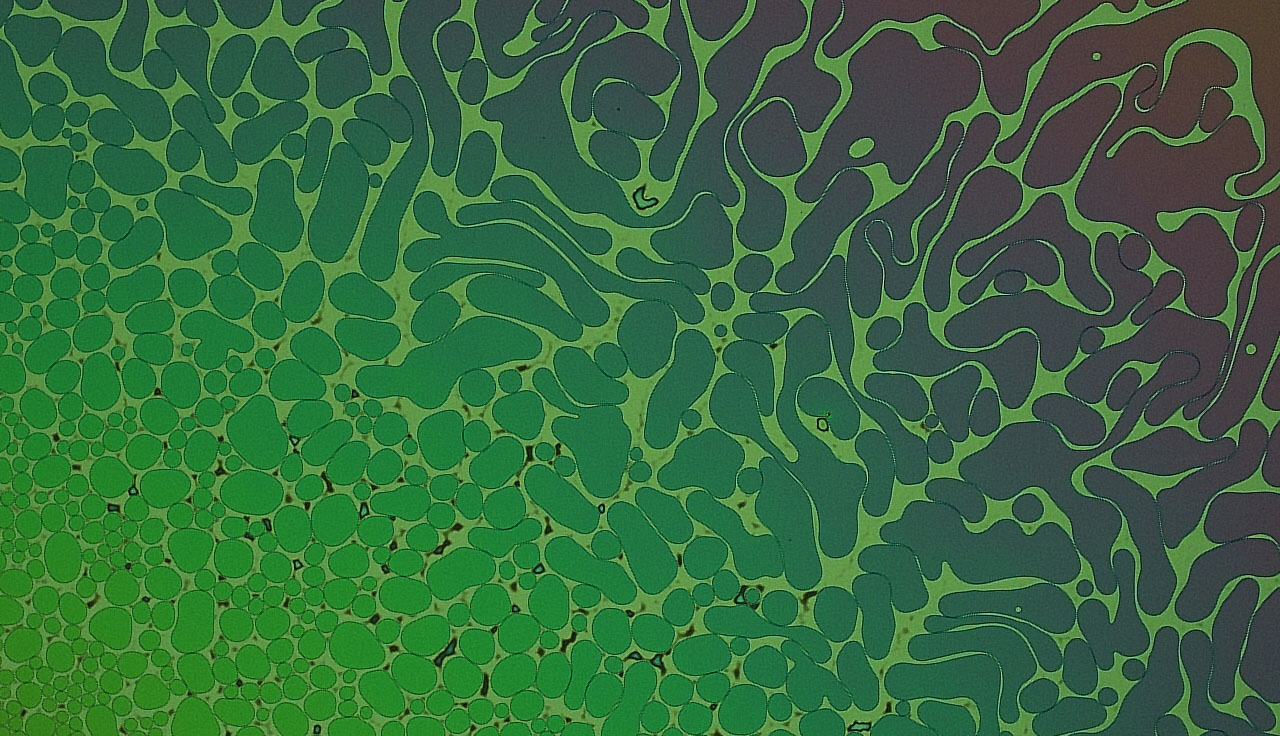

ANFF-Vic Image of the Year Competition

This competition is now closed. Please head to the news feed for the latest information.

It’s time to enter ANFF-Vic’s Image of the Year Competition.

The winner will receive a $200 cash prize as well as recognition through our media channels and featured placement on Nanomelbourne.com.

Submissions are now open – send your high resolution images of work conducted within ANFF-Vic in jpg, png or tif format to mcn-images@nanomelbourne.com with a short description of the image.

In this year’s competition, the public will decide the winner. Once a shortlist has been selected, we will upload the images to our twitter page, @Nanofab, and the image with the most likes and shares will win.

All users are eligible, there is no limit to the number of times that you can enter, and no particular theme for the competition.

Get submitting!

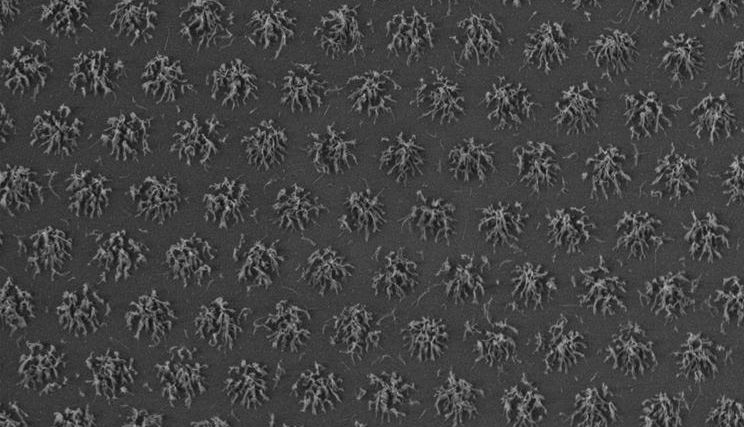

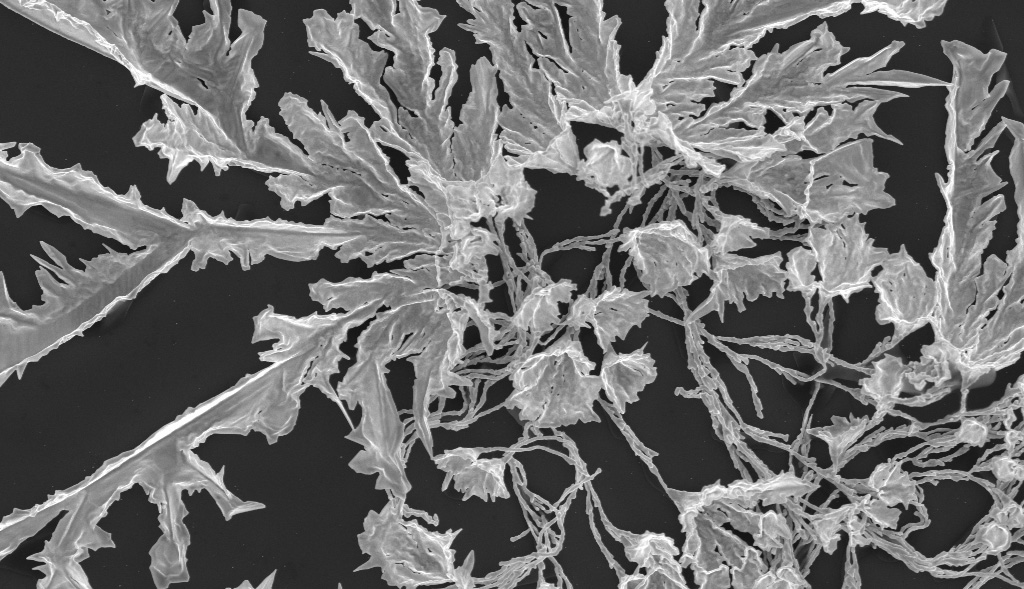

Title: “Seaweed”

Title: “Seaweed”