MCN at National Manufacturing Week

National Manufacturing Week (NMW) will be taking place next week at the Melbourne Convention Centre from 26-29 May 2015. NMW is the only fully integrated annual manufacturing exhibition showcasing the latest products and constantly evolving technologies in the expanding manufacturing market.

Following the success of the NMW Solutions Theatres in 2014, NMW 2015 will feature a fantastic program of free education and networking, showcase two unique free-to-attend theatres on the exhibition floor, including the R&D Hub, and Digital Solutions Theatre. The R&D hub will showcase new ideas in manufacturing design and technology and will aim it is to bridge the gap between innovation and development.

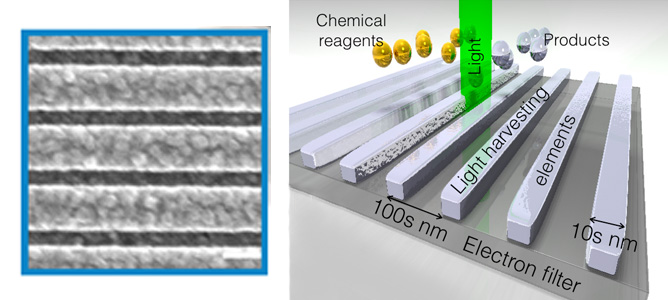

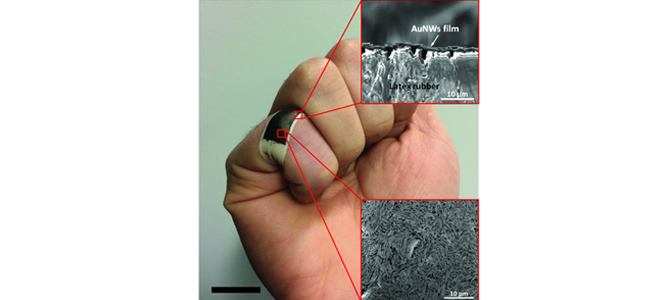

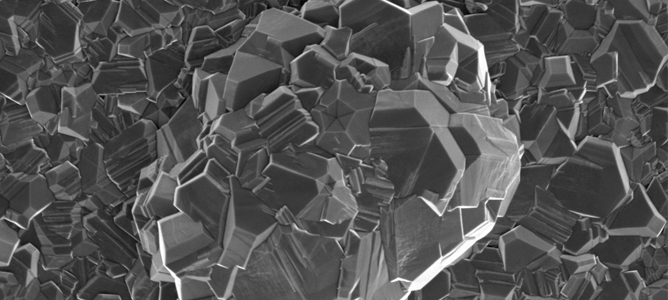

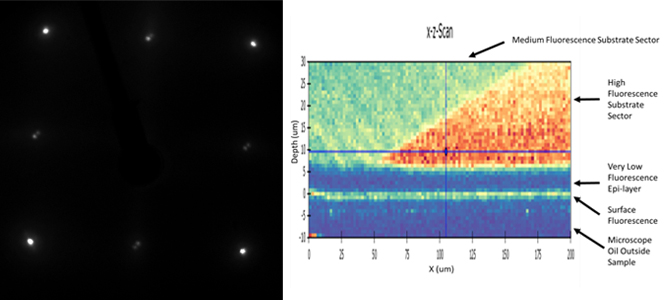

MCN’s booth (number 5410) will be situated nearby the R&D hub – we encourage you to drop past, chat to our expert staff and inspect MCN’s new displays which feature a range of processes including, DRIE, EBL holographic shims, diamond deposition, optical profilometry, 3D printing and more.

A collaborative space for start-ups

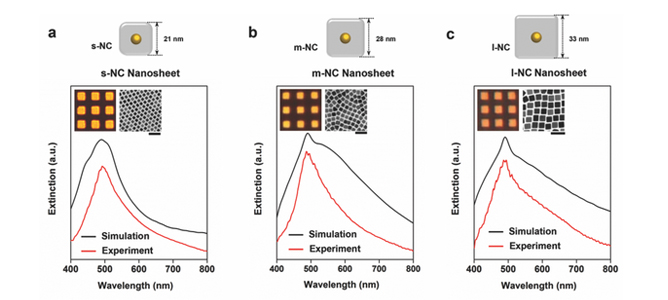

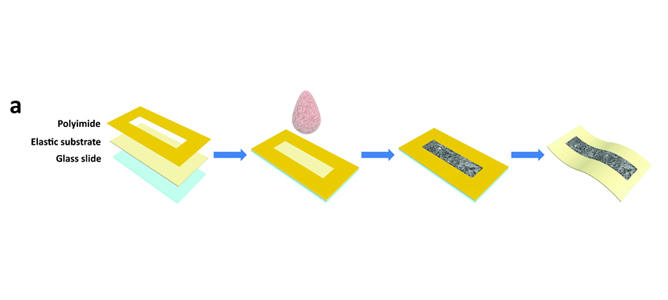

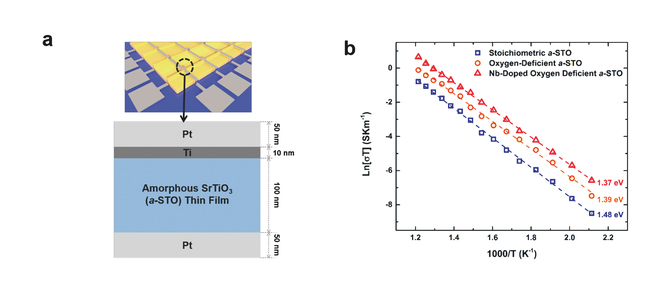

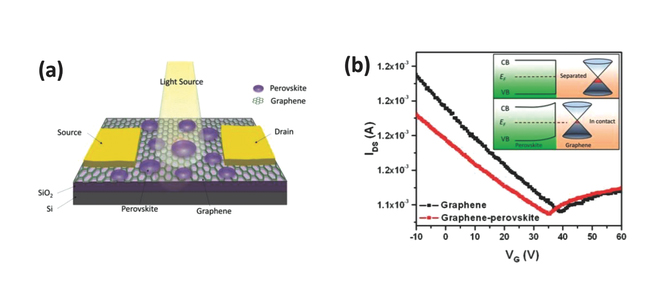

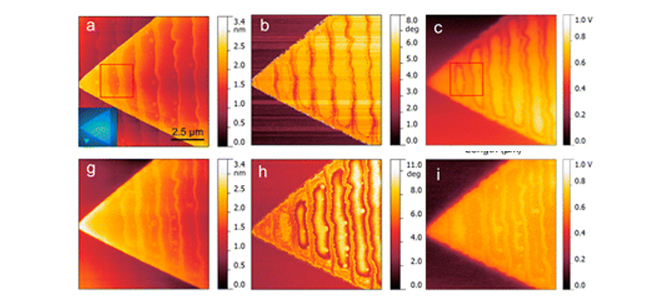

Artificial leaves enhance light to energy conversion

We’re hiring!

Marketing & Communications Officer

MCN is currently looking for a Marketing and Communications Officer. The successful candidate will have excellent written communication skills and strong attention to detail, exceptional organisational skills, a strong sense of creativity and design, as well as analytical and problem‑solving skills.

Key selection criteria include:

1. A degree in a relevant field OR experience in public relations, marketing, communications or similar, OR an equivalent combination of relevant experience and/or education/training.

2. Proven, high-level written and oral communication and interpersonal skills with proven experience in writing articles, corporate communications and technical information for websites and brochures for a variety of audiences.

3. Highly competent computer literacy skills including experience with the Adobe Creative Suite, web content management (ideally wordpress), electronic direct mail programs (ideally mailchimp) and the ability to acquire skills in the use of new software packages.

4. Highly competent research, creative design, analytical and problem-solving skills including a demonstrated capacity to show initiative and take responsibility for a broad range of activities and functions as well as develop solutions to complex problems.

5. Highly effective work organisation skills including the ability to plan, prioritise tasks, work effectively under pressure, achieve goals within established timelines and changing priorities and operate in a methodical manner paying particular attention to detail.

6. Project management experience, specifically the ability to organize and coordinate events and logistics.

7. Proven ability to liaise, consult and negotiate with clients both internal and external and at all levels.

More details can be found here.

Applications close Thursday 21 May 11:55pm AEST