Seminar series highlights

The MCN 2014 Public Seminar Series drew to a close last month with the energetic and fast-paced PhD Frenzy. Many people from the MCN community came together over the course of the series to learn from thought leaders and some of MCN’s most successful clients.

Diamond on demand grand opening

Presenting to a packed marquee, Dr. Alastair Stacey, Professor Steven Prawer and Professor Lloyd Hollenberg provided captivating examples of the real-world applications of synthetic diamond. Giving a brief history of synthetic diamond and its uses in scientific research, Dr Stacey placed MCN’s Diamond Deposition Suite in the broader context of global research, sharing his excitement for what it means to have two state-of-the-art systems available for use in Victoria. Professor Prawer followed this with a summary of the Bionic Eye project and the significance of diamond in the creation of high-acuity devices which can be safely and successfully implanted in the eye. Lastly Professor Hollenberg gave an overview of quantum reality and technology, leading into diamond-based quantum bio-sensing, including the creation of a Nano-MRI for biological systems and the real time imaging of neuronal networks.

Concluding the seminar, Minister Pyne delivered an address highlighting the Federal Government’s commitment to financing crucial scientific infrastructure through the continued funding of the National Collaborative Research Infrastructure Strategy (NCRIS). This funding has now been confirmed with a value of $150 million from July 2015.

Officially launching MCN’s newly commissioned diamond deposition suite, Minister Pyne then participated in a tour of the centre, showing great interest in the work undertaken at the MCN and choosing to gown up and enter the cleanroom for a closer look.

Nanofabulous for industry

Held in May, the Nanofab-ulous for Industry seminar highlighted the exciting work of MCN’s industry clients, much of which has not previously been publicly shared.

Kicking off the morning, Vice President of Research and Development at Vaxxas, Angus Forster highlighted the evolution of the Nanopatch TM, discussing the common pitfalls of start up companies and the steps that Vaxxas are taking to avoid them. Noting MCN’s important role in maximizing the momentum gathered in the early stages of Vaxxas, Angus said that a significant aspect of development from a great concept to a great product is having access to local technology resources. Having access to facilities such as MCN minimizes the time between product concept and demonstrated clinical performance as well as the potential gap between functional product performance and the final manufactured product. Partnership with MCN has allowed Vaxxas to increase both yield and volume of production by transferring the DRIE process from 4 to 6 inch wafers and processing wafers in parallel by using both of MCN’s DRIE systems.

Managing Director of Eden BDM, Alex King discussed the development of the world’s first micro-flow battery for use in electric powered vehicles (EPV). Alex highlighted the breakthrough technology which has enabled design of the battery – Edenglass. Edenglass is a substance comprised of a series of self assembling nanoparticle capacitors which hold and amplify electric charge. Incorporating the Edenglass into a microfluidic design created at MCN, Eden BDM are focused on creating a new style of EPV battery to combat the issues with current devices namely their huge cost, weight, recharge requirements and safety concerns. Eden’s design would see 168 microfluidic chips stacked together to create a battery unit that is able to recapture the expended energy of a moving car, minimizing the need for recharging and allowing the EPV to reach potentially unlimited mileage.

Chairman and Director of MuPharma Pty Ltd, Harry Unger showcased SonoEye TM, the first non-invasive device used to deliver medication to the eye for the treatment of macular degeneration. Currently the only way to deliver treatment to the retina is with a series of monthly injections into the eye which are invasive, painful and hold a series of associated risks. In contrast the SonoEye TM Device is a hand held device that generates an ultrasound to move the chosen drug through a gel placed on the applicator, which when held on the cornea, increases the permeability of the target tissue and moves the drug through to the retina. Through design collaboration with MCN, MuPharma Pty Ltd was able to increase the efficacy of the SonoEye TM and extend its impact for customers.

Director of Research and Development at Innovia Security, Gary Power shared how optically variable devices such as holograms have helped create counterfeit proof banknotes, drivers’ licenses and educational certificates. Having just celebrated 25 years of polymer banknote technology, Innovia Security, in conjunction MCN, have developed a new manufacturing capability for these devices which utilize nanofabrication techniques to write 75GB of data into a one inch square image for the creation of highly detailed, refractive holograms.

Managing Director and founder of Micro-X Pty Ltd, Peter Rowland discussed the development of a lightweight, mobile medical x-ray system for hospitals. Working closely with MCN in its quest for an efficient, miniature, high performance cold-cathode x-ray tube, Micro-X have utilized carbon nanotubes, to create an energy efficient system which is much smaller then typical x-ray systems, enabling easier portability and maneuverability.

The seminar provided an amazing insight into just some of the exciting work that is carried out at MCN and the extensive range of fields for which nanofabrication can be relevant.

PhD Frenzy

Thirteen of MCN’s brightest and most passionate students took to the stage in late June to share their theses and the work they have been undertaking at MCN. The students spoke on a range of topics from the manipulation of microfluidic systems to nano-optics, from MEMS resonators to photonic crystals, highlighting the importance of their work and the methods they are utilising, all in under 2 minutes each.

The panel of judges, comprising Professor Michael Fuhrer, Professor Mike James, Brett Henderson and Julie Rothacker, judged the students on their presentation style and content, asking a further question into the science and commerciality of their work following each presentation.

Taking out the grand prize of the iPad Air in first place, David Collins gave an energetic and witty presentation on the manipulation of microfluidic systems using surface acoustic waves. He highlighted how future sensing devices could be incorporated in household items such as toilets to warn people of illness before symptoms show.

In second place, Romiza Mazid discussed the stability of biomolecules using ionic liquids, passionately describing the importance of this work in the creation of stable vaccine solutions for the third world, in order to remove the necessity for refrigeration and specific storage environments.

Tied in third place, Upulie Divisekera spoke of her mission to cure cancer through the delivery of nanoaprticles across cell membranes through engineered pore forming proteins in order to best deliver drugs to the site of cancer, while Masrur Morshed Nahid gave the audience a glimpse into the future where phones are both flexible and transparent and where laptops can be worn as a wristband. Discussing organic electronics polymer film morphology and device physics, Nahid showcased the science behind the vision for these future devices.

MCN thanks all those who participated in the event and helped to make it such a success.

5S training and induction refreshers

Over the last six months, MCN staff have embarked on a mission to overhaul systems to make MCN a more efficient, organised and methodical workplace by undertaking a Lean training and business improvement program.

The program looks at optimising the processes and systems already in place to make them more efficient and simple for all employees and users to follow. This is especially important at MCN as many processes must be followed by a wide range of staff, visitors and users, with a range of experience levels.

All MCN technical staff are now accredited under the Lean program and have implemented a 5S program - sort, set in order, shine, standardize, sustain – to provide a system of reliability and accountability in all facets of MCN’s day-to-day activities. This is an industry standard that provides a structured, productive and clean working environment and includes the implementation of cleaning rosters, labelling systems to ensure shared items are kept in the right place, removal of unnecessary items in shared spaces, systems for stock replenishment, as well as instrument care and maintenance.

Many users will have noticed the signs of the 5S program around the MCN building in the labs, cleanrooms and shared meal and meeting spaces. On Monday September 1, MCN will be running a 5S training day for registered users of the facility. The session will start at 11 with a workshop in the boardroom and will include a light lunch. This will then be followed with a hands-on session in the labs from 2-5pm.

All users are strongly encouraged to attend the training workshop and are asked to assist with the implementation of this program by following rosters, replacing items in their correct place and taking note of signs and labels around the building. Through working together to follow these new systems, staff and users can work together to build a stronger, safer and more productive workplace for everyone.

MCN’s bi-annual induction refresher will be running from 10-11am on the morning of the 5S training session, as well as all the other days that week (1 – 5 September) so that users are able to attend both in succession. Both events will be held in the MCN board room and registration is not required.

A spotlight on electronic skins

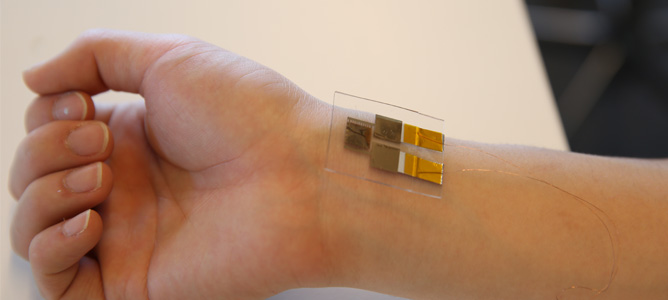

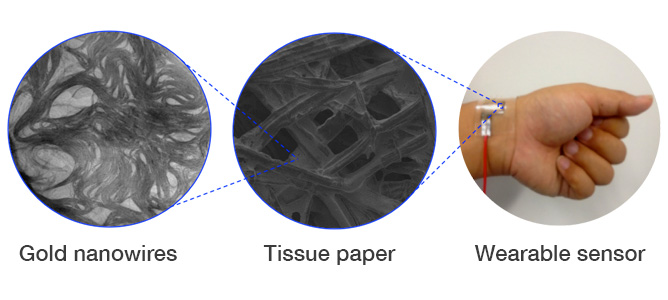

Flexible electronics and lightweight pressure sensing devices are expanding the boundaries of technology into the fields of soft robotics, electronic skins and flexible displays. Current rigid circuit board technologies are limited in their applications, particularly with regards to medical devices and bionics. MCN Technology Fellow, Associate Professor Wenlong Cheng from Monash University, has been leading a team in the development of stretchable, elastomeric conductors for use in pressure sensing.

The focus of this project is the creation of pressure sensors which enable portable pulse and heart rate monitoring, as well as body movement sensing and are hoped to ultimately lead to electronic skin as the future of medical devices.

Flexible electronics have been the focus of much research attention recently, with work involving various nanomaterials, nanowires, carbon nanotubes, nanoparticles and grapheme being undertaken. Most of these are based on force-induced changes in capacitance or piezo-electricity, while Associate Professor Cheng’s group has been creating sensors based on resistive pressure. The advantage of this approach is the simplicity of the device fabrication as well as the relatively low amount of energy required to operate the device.

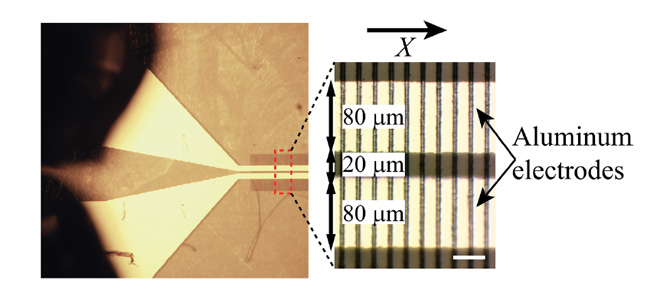

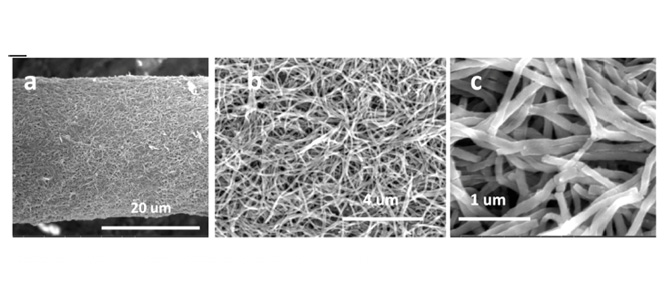

Utilising the facilities at MCN, his team has developed a simple, yet efficient, low-cost nanotechnological approach to integrating ultrathin gold nanowires into tissue paper to create a flexible sensor. The gold nanowires are just 2nm thick, yet tens of microns long and are both mechanically flexible and robust. Once nanowires have been soaked into tissue paper, it is then sandwiched between two thin layers of PDMS - one blank and the other patterned with an interdigitated electrode array - and attached to wiring to create a wearable sensor that can provide readings of blood pressure, heart rate and body movement. Such sensors are so sensitive, that tiny forces from blood pulses and acoustic vibrational forces can be accurately detected. What’s more, these devices are robust and can be fabricated in large quantities at low cost using scalable wet chemistry processing steps.

This development of soft electronics holds huge potential for portable health monitoring devices. Associate Professor Cheng will be looking at the commercial development of this project next.

Associte Professor Cheng can be heard discussing these sensors on the BBC radio program, Click. The interview starts approximately 6 minutes into the show.

You can read more about this project in the Nature Communications Paper, published in February 2014.

New furnace and optical profilometer

Four stack furnace

To compliment the high temperature furnace facility already available at the MCN, a new four-stack horizontal furnace is currently being installed in the class 10,000 cleanroom. This new furnace will allow batch processing of up to 150mm wafers and will provide access to high temperature processing (>1000 degrees Celsius) of silicon and other substrates. The system features a HEPA controlled loading station as well as four individual processing tubes to cater for dopant diffusion, annealing and the low-pressure chemical vapour deposition of silicon nitride.

This furnace will be available to users in the next few months. Please contact paul.spizzirri@nanomelbourne.com for more information.

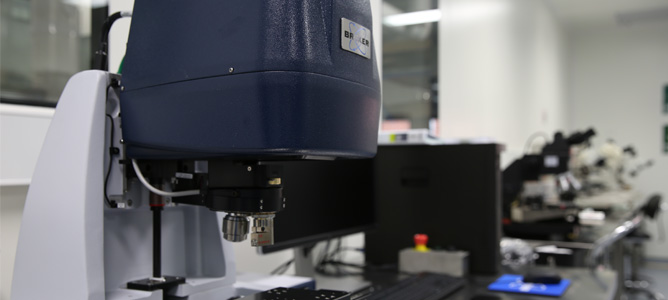

Optical Profilometer

MCN is the first facility in Australia to install an all-new Bruker Contour GT-I Optical Profilometer – a fully automated, desktop optical microscope which measures surface features over a range of angles. The combination of tip/tilt in the head with automated staging and objectives, as well as vibration resistant measurement techniques, make the Contour GT-I ideal for measure on demand industrial requirements.

The Contour GT-I joins MCN’s Ambios XP 200 profilometer and provides a 3D optical profilometry capability. Optical profilometry employs phase-shifting and/or vertical scanning interferometry to resolve the topology of complex 3D structures. The technique marries precision z-axis control with interference based techniques to resolve features from the angstrom to millimetre scale. The technique lends itself well to die-based measurements for ISO/QA and large area mapping.

The optical profilometer will be available to users from August 2014. Please contact sean.langelier@nanomelbourne.com for more information.

COMS conference 2014

The commercialization of Micro, Nano and Emerging Technologies Conference will be held this year in Salt Lake City, Utah from 12 - 15 October.

The 19th COMS Conference to be held, this year it partners with nanoUtah, Utah's regional annual nanotechnology conferene.

Key note speakers includes Dr. Klaus Dieter Lang, Director of Fraunhofer Institute for Reliabiloty and Microintegration; Fred Lampropoulos, Chairman and CEO of Merit Medical Systems and Dr. George Gruner from the University of California Los Angeles.

MCN will be attending COMS 2014 - the only conference world-wide to be dedicated to the commercialisation process for micro and nanofabrication technologies. Bringing together leaders in nanofabrication from across the globe, COMS creates productive partnerships and focuses on entrepreneurship and marketable nano solutions.

Click here for more information.

Technology fellow presentations online

A selection of presentations from the MCN Technology Fellow showcase are now online. You can watch them below or at our Youtube channel, NanofabTV.

Professor Tim Davis from CSIRO discusses the all optical modulation of light by a metamaterial of nanoscale circuits. Prof. Davis showcases the ways in which light can be used to control other light beams to create optical circuits which mimic electrical circuits but operate the the speed of light. Delving into the artificial metamaterial which his team is creating, Prof Davis talks about the huge potential for these devices.

Dr. Yonggang Zhu from CSIRO discusses microfluidic chips for chemical and biological synthesis and integrated lab on a chip devices for sensing applications. He highlights the ways in which lab on a chip devices are useful for chemical and biological sensing, sample processing as well as materials synthesis.

Associate Prof. Ray Dagastine from Melbourne University discusses the nanomechanical properties of micro-capsules which make up foams and emulsions as well as the methods used to study them to asses their stability and weaknesses.

Dr. Brian Abbey from La Trobe University discusses the strain mapping at multiple length scales and the experimentally validating predictive modelling his team is undertaking. Dr. Abbey highlights some of the novel characterisation techniques they are developing to feed into predictive modelling for materials.

Technical interns wanted

Internship opportunities

The Melbourne Centre for Nanofabrication (MCN) and its partner laboratories within the ANFF Victorian Node are seeking expressions of interest from suitably experienced candidates for an internship program.

Successful applicants will be partnered with an MCN industry client to perform work as part of an industry project.

Applicants should possess an undergraduate degree in a science or engineering discipline that is strongly linked to micro/nano technologies, and ideally be pursuing (or recently completed) postgraduate studies in this field. Successful candidates will be offered short-term projects on a casual, part-time or full-time basis, for duration of 2-6 months. Projects may be located at MCN or at any of the ANFF-Victoria partner laboratories.

To apply, please send your CV, detailing your skills and experience in micro/nano technologies (maximum of 2 pages) to mcn-enquiries@nanomelbourne.com by midnight 30 September 2014.

Industry clients wanted to participate

The MCN is also seeking expressions of interest from industry clients for participation in this co-funded intern program.

The framework of the program includes contributions from both MCN and the industry partner. Partners are able to select the appropriate intern for the project from a pre-selected group who have skills relevant to micro/nano technologies. Even though all interns will be closely supervised by a full-time process engineer on staff at MCN, the quality of work may be dependent on the skills of the intern.

Relevant activities should be short-term projects with a duration of 2-6 months and may be in a casual, part time or full time capacity, depending on the availability of each intern candidate.

Work undertaken at MCN as part of this intern program will be consistent with the MCN IP Policy, whereby all product-related IP is owned by the client and process-related IP is retained by MCN.

To partake in this program, please fill in the attached form with details of the project, estimated timeline and desired intern skills and submit it to Dwayne.kirk@nanomelbourne.com by midnight 30 September 2014. Intern projects are expected to start in September-October.

New faces at MCN – Shan and Gediminas

MCN welcomes two new staff members to the team – Shan Don as the coordinator of Design House and Gediminas Gervinskas as a Process Engineer.

Shan Don works at MCN in a part time capacity at the ANFF Design House Coodinator. With more than 18 years IT experience in a variety of organisations and locations (including Russia, Sri Lanka and the USA), he brings a broad range of technical expertise to the Design House project. Shan holds a Bachelor of Science and a Masters of Science as a Systems Engineer from Vladimir State University, Russia.

Gediminas Gervinskas received a BSc and MSc in physics from Vilnius University in Lithuania in 2007 and 2009, respectively. He has three years of experience as an engineer in the Heavy Ion Beams Analysis group at the Physics Institute in Vilnius.

In 2010 he began working at MCN under Technology Fellow, Prof. Saulius Juodkazis. His work focused on creation of optofluidic platform for integration of plasmonic, micro-photonic, and fluidic functionalities for applications in bio-/environmental-/medical sensing.

At MCN, Gediminas is responsible for the FEI Dual Beam Focused Ion Beam and Scanning Electron Microscope (FIB-SEM), FEI Nova NanoSEM (FEG-SEM) as well as the Hitachi TM3030 SEM (Tabletop-SEM) with Oxford EDX instruments.

Noteworthy publications

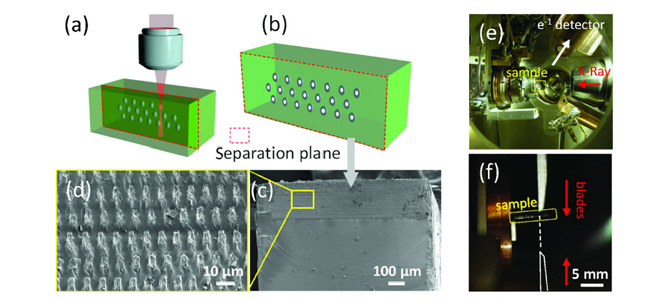

Congratulations to MCN Technology Fellow, Professor Saulius Juodkazis and MCN staff member, Gediminas Gervinskas, who co-authored the paper entitled “Phase Transformation in Laser-Induced Micro-Explosion in Olivine (Fe,Mg)2SiO4,” recently published in Advanced Engineering Materials. The paper explores micro-explosions generated by tightly focused single pulses of a femtosecond laser in olivine, showing that they produce change of iron valence state. Chemical and structural changes were investigated using synchrotron X-ray spectroscopy and Raman scattering. This study confirms that this mechanism may present a general pathway towards the creation of novel crystalline and amorphous nano-materials. (see figure 1)

Congratulations to MCN staff member, Dr. Ricky Tjeung, as well as MCN Technology Fellows, Professor James Friend and Dr. Peggy Chan who co-authored the paper “In Situ Generation of Tunable Porosity Gradients in Hydrogel-Based Scaffolds for Microfluidic Cell Culture,” recently published in Advanced Materials. The paper shows that an anisotropic matrix, which allows users to alter its properties and structure in situ after synthesis, offers the important advantage of being able to mimic dynamic in vivo microenvironments, such as in tissues undergoing morphogenesis or in wounds undergoing tissue repair. In this study, in situ tunable porosity gradient on the chemotactic response of cancer cells is studied both in the absence and presence of chemoattractant. This platform illustrates the potential of hydrogel-based microfluidics to mimic the 3D in vivo microenvironment for tissue engineering and diagnostic applications. (see figure 2)

Congratulations to Didit Yudistira et al who recently published “UV Direct Write Metal Enhanced Redox (MER) Domain Engineering for Realization of Surface Acoustic Devices on Lithium Niobate” in Advanced Materials. The paper looks at a new and highly versatile domain patterning method—ultraviolet direct write metal enhanced redox (UV direct write MER)— to achieve deep domains with practically no thermally-induced damage on the surface of lithium niobate crystals. This new technique enables the fabrication of practical piezoelectric acoustic superlattice structures on the most widely used crystal cut for surface acoustic wave applications. This is the first demonstration of a UV direct write surface acoustic wave transducer reported to date, made possible only due to the unique qualities of the MER domain engineering process. (see figure 3)

Congratulations to Daohong Zhang et al who recently published the paper entitled “Core-Spun Carbon Nanotube Yarn Supercapacitors for Wearable Electronic Textiles,” in ACS Nano. The paper presents a core/sheath structured carbon nanotube yarn architecture and a method for one-step continuous spinning of the yarn for the creation of long linear supercapacitors. In the yarn, the carbon nanotubes form a thin surface layer around a highly conductive metal filament core, which serves as current collector so that charges produced on the active materials along the length of the supercapacitor are transported efficiently, resulting in significant improvement in electrochemical performance and scale up of the supercapacitor length. The long, strong, and flexible threadlike supercapacitor is suitable for production of large-size fabrics for wearable electronic applications. (see figure 4)

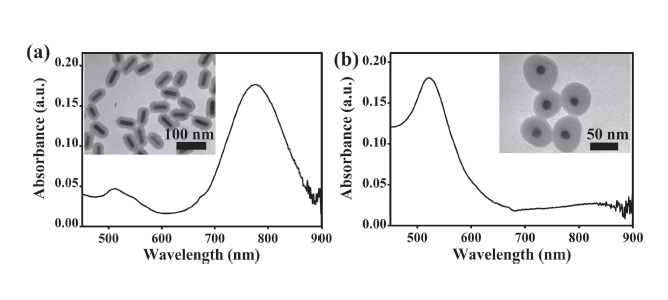

Congratultions to Jiaweng Yong et al for their paper, “Gold-Nanorod-Assisted Near-Infrared Stimulation of Primary Auditory Neurons,” recently published in Advanced Healthcare Materials. This paper explores the use of near infrared lasers to stimulate neuronal tissue due to its potential for direct, non-contact activation at high spatial resolutions. Cultured rat primary auditory neurons incubated with silica-coated gold nanorods were investigated with near infrared lasers. The nanorod-treated auditory neurons show a significant increase in electrical activity compared with neurons which are incubated with non-absorbing silica-coated gold nanospheres and control neurons with no gold nanoparticles. This demonstrate the potential to improve the efficiency and increase the penetration depth of Inelastic neutron scattering by labeling nerves with gold nanorods and then exposing them to infrared wavelengths in the water window of tissue. (see figure 5)

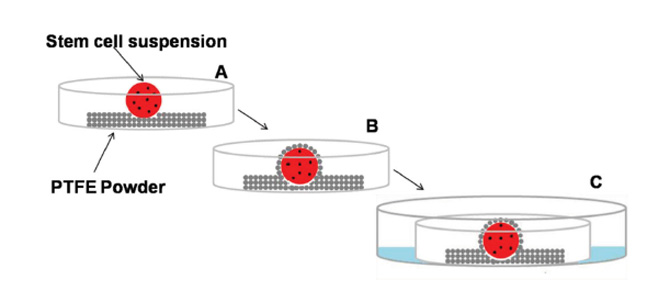

Congratulations to MCN Technology Fellow, Dr. Peggy Chan who co-authored the paper, “Cardiogenesis of Embryonic Stem Cells with Liquid Marble Micro-Bioreactor,” published in Advanced Healthcare Materials. The paper looks, for the first time, at the feasibility of differentiating embryonic stem cells into cardiac lineages within liquid marbles. Results highlighted demonstrate that the liquid-marble technique is an easily employed, cost effective, and efficient approach to generate embryoid bodies and facilitate their cardiogenesis. (see figure 6)

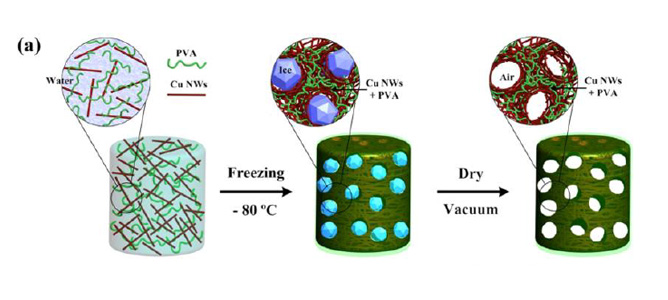

Congratulations to MCN Technology Fellow, Assoc Professor Wenlong Cheng who co-authored the paper entitled, “Manufacturable Conducting Rubber Ambers and Stretchable Conductors from Copper Nanowire Aerogel Monoliths,” recently published in ACS Nano. The paper reports on a low-cost, simple and efficient strategy to fabricate ultralightweight aerogel monoliths and conducting rubber ambers from copper nanowires. A trace amount of polyvinyl alcohol substantially improved the mechanical robustness and elasticity of the copper nanowire aerogel while maintaining a high electrical conductivity. Remarkably, the copper nanowire aerogels could be further embedded into PDMS resin, forming conducting rubber ambers. The ambers could be further manufactured simply by cutting into any arbitrary 1D, 2D, and 3D shapes, which were all intrinsically conductive without the need of external prewiring, a condition required in the previous aerogel-based conductors. (see figure 7)

Research into zinc oxide nanoparticles allays sunscreen concerns

In a paper published in ACS Nano in November 2013, researchers from MCN, The Australian Synchrotron, CSIRO, RMIT and Monash University showcased ground-breaking characterisation techniques which were used to enable research into the human immune response to zinc oxide nanoparticles.

Zinc oxide nanoparticles are used in many consumer products such as sunscreen since they are largely insoluble in water and invisible to the eye, unlike larger white zinc particles which remain white on the skin. However, the behaviour of zinc oxide nanoparticles in biological systems is not well understood. This led the team of researchers to delve into what happens to these nanoparticles after they are absorbed into our skin.

The research team used x-ray fluorescence to image immune cells which had been treated with zinc oxide nanoparticles. Using the world-class Maia x-ray fluorescence detector at the Australian Synchrotron, the researchers were able to count how many of these tiny particles had been absorbed into the cells.

In order to observe the nanoparticles once in the immune cells, the researchers used the Focused Ion Beam Scanning Electron Microscope installed at MCN to mill away very thin layers of the cell (100x thinner than a human hair), re-imaging the cell as they went. Combining these different techniques produced a unique collection of high-resolution images that allowed the team to observe the immune cells breaking down the nanoparticles as they moved deeper into the cell.

''This is the first time that we have shown that the cells of the immune system can break down the nanoparticles directly,'' said Australian Synchrotron and CSIRO bioinorganic chemist Simon James. ''Previous work was only able to infer that.''

The images showed that on average, 60,000 nanoparticles made it into a single white blood cell. ''60,000 nanoparticles is a tiny, tiny amount of zinc,” Dr James said, “especially seeing as the cells are able to break the nanoparticles down."

What’s more, 50 to 60 per cent of the zinc oxide nanoparticles were entirely broken down by the macrophages within just 24 hours of entering the cells, with the remaining 40 per cent in the process of decomposition. Dr James explained that in the study, the nanoparticles did not reach the cell nucleus, demonstrating that human macrophages function as expected, ingesting and breaking down any zinc oxide nanoparticles before they can enter the blood stream.

“In response to some concerns, this research shows us conclusively that the nanoparticles in sunscreen are unlikely to cause harm to beach-goers," said Prof Ian Olver from Cancer Council Australia, “unlike the sun’s damaging UV rays which we know lead to higher rates of skin cancer and skin damage.”

The unique imaging techniques used in this study have demonstrated that correlative photon and ion beam imaging can provide both high-resolution and statistically powerful information on the biology of metal oxide nanoparticles at the single-cell level. This approach promises ready application to broader studies of phenomena at the interface of nanotechnology and biology.