Internship program connects with industry at MCN

MCN’s internship program has hit the ground running, with four interns recently joining MCN’s professional staff. With a range of experience in nanotechnology, chemical engineering and physics, the interns were selected by our industry partners to work on projects particular to their skills. MCN welcomes James Griffith, Mathew Lui, Lachlan Pierce and Siew Pei Hoo!

James Griffith completed a Masters in chemistry at Cardiff University in the UK. He brings with him experience as a laboratory analyst looking at electrochemical oxidation using boron doped diamond and the manufacture and use of electrochemical cells for water treatment. James will be working under the guidance of John McCormack, senior researcher from Eden BDM Limited, on a continuing program of prototype development toward the Eden nanoflow battery.

Mathew Lui is currently completing a Masters of engineering science at Monash University on the effect of complex platelet shear rate history on thrombus growth. He brings with him experience working at MCN in mask writing and development, photolithography and soft lithography as well as deep reactive ion etching. Mathew will be working with MCN’s Senior Process Engineer, Bernie Orelup on a range of projects for MCN clients.

Lachlan Pierce completed a Masters of nanotechnology at La Trobe University and brings with him project experience in the investigation in the use of ionic liquids in electrochemiluminescence; the design and construction of microfluidic devices; as well as the study of a nickel/C60 interfacial system by near edge x-ray absorption fine structure and x-ray photoelectron spectroscopies.

Siew Pei Hoo completed a PhD in chemical engineering at Monash University which focused on a novel hydrogel developed from renewable polysaccharide cellulose as a green chemistry which could be used to replace traditional petroleum based polymers. She also has experience in tissue scaffolding and biomaterial engineering and functionalisation.

Both Lachlan and Siew will be working with Trajan Scientific and Medical which is focused on developing and commercialising technologies that enable analytical systems to be more selective, sensitive and specific for biological, environmental or food related measurements, especially those that can lead to portability, miniaturisation and affordability.

Trajan engaged with MCN to continue development of porous polymer monoliths designed as a means of chemical separation, and to take this work from the research domain into a viable manufactured product. General manager of chemistry platforms at Trajan, Dr. Rick Barber said, “MCN is a fundamental interface between the research world and the manufacturing line. The intern program is a fantastic opportunity for us to fast track the research and development stage of this project as we are able to work on parallel applications and work through the initial research work faster, to achieve an end-product more swiftly.”

Lachlan and Siew will be looking at the parametric studies to understand the critical parameters for creating robust monoliths in order to optimize the manufacturing processes. Dr. Barber said, “the benefit of working with two interns concurrently is that they can work on different parts of the same puzzle and then validate each other’s work.”

About the program, MCN managing director, Dwayne Kirk said, “this is highly beneficial for industry because it’s quick and easy for them to access additional specialists with experience relevant to their projects. MCN matches the interns to specific projects to make it as simple as possible for our clients, who then benefit from having interns working solely on their projects to the high standards of MCN’s staff. We are pleased to see that there has been such an enthusiastic uptake from our clients and encourage others who think they might benefit from working with an intern to contact us.”

Technology Fellow receives VC award for research excellence

MCN would like to congratulate our most recent Technology Fellow, Dr. Alexey Glushenkov who was recently awarded the Vice Chancellor’s Award for Research Excellence (Early Career Research) at Deakin University. The award recognises individuals who have contributed to long term goals and research vision of Deakin University.

Alexey undertook his technology fellowship at MCN earlier this year and has a particular interest in the applications of nanostructured electrodes in electrochemical energy storage. His research project is centred around the electrode materials for lithium ion and sodium ion batteries as well as electrochemical supercapacitors.

A recent trial as part of this project saw a conformal deposition of 10nm of aluminium oxide onto boron nitride nanotubes by Atomic Layer Deposition (ALD). A normally challenging structure to coat uniformly, the nanotubes were coated by a homogeneous, 10nm thick layer of aluminium oxide using MCN’s ALD Savannah S100 instrument. The ALD techniques available at MCN are able to achieve highly conformal, continuous, pin-hole free depositions on complex surfaces and porous structures.

Alexey is aiming to use a similar technique to provide coatings for electrodes in batteries to provide an artificial surface layer to separate electrodes from direct contact with electrolytes in batteries. Such a surface layer is capable of ionic conduction and does not interfere with battery operation, while it works to reduce unwanted side effects caused by the contact of electrodes with electrolytes and result in better cyclic stability and reliability of batteries.

MCN looks forward to working with Alexey over the coming months on other exciting aspects of this project.

Fighting resistance to antibiotics

As resistance to antibiotics is becoming increasingly common, it has become more important to understand the mechanism by which antibiotics work on bacterial cells, and to develop new antibiotics which can be used against ‘super bugs.’

In order to understand the process by which potential combinations of antibiotics kill multi-drug resistant bacterial cells, a joint force from Monash Engineering (Mr. Boyin Liu and Dr. Jing Fu) and Monash Pharmaceutical Sciences (Professor Jian Li and Dr. Tony Velkov) together with the MCN, the Australian Synchrotron and the University of Queensland have been working on novel imaging approaches to assess the cellular responses of bacterial cells to the treatment of antibiotics, including the last-resort polymyxins.

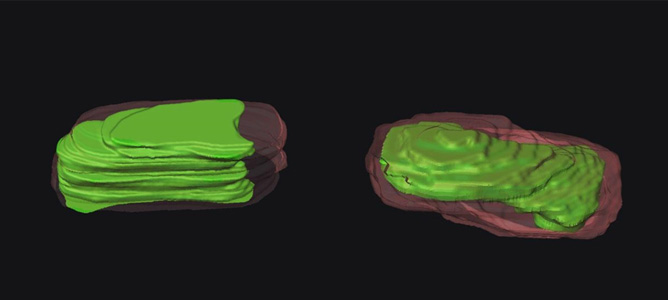

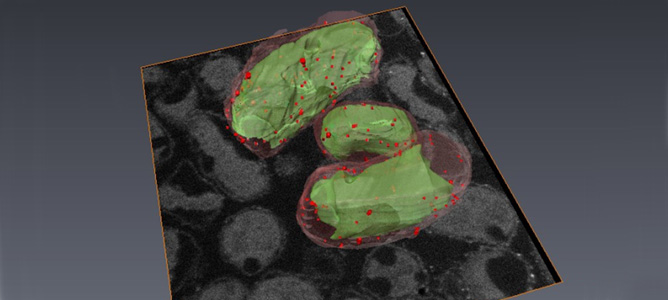

The team has used the Focused Ion Beam (FIB) tool at MCN to mill away 25nm slices of a cell of resistant bacterial isolate (Klebsiella pneumoniae) recently discovered in Queensland. After the removal of each slice, high-resolution scanning electron microscope images were taken and then reconstructed into a 3D model of a whole bacterial cell to reveal the effect of the antibiotic in different cellular regions.

The 3D models of both treated and untreated cells were reconstructed and compared. Their finding confirmed the invasion of polymyxin B on the cell envelope and the subsequent depletion of cytoplasmic materials. The results provided clear evidence for using rational antibiotic combinations to combat bacterial ‘superbugs.’

In the ongoing research, FIB is also being used to slice the bacterial cell to expose the interior surface, after which Atomic Force Microscopy (AFM) is employed to probe the intracellular changes and measure their mechanical properties. The investigators are also employing a single-molecule AFM tip functionalisation technique, Synchrotron imaging and secondary ion mass spectrometry to identify the chemical signatures due to antibiotic treatment. Their research is funded by the Australian NHMRC and the US National Institutes of Health (NIH).

You can read more about this project in this paper published in IOP Science in September this year.

ANFF Design House workshops

Bringing together software packages from Synopsys, Coventor and TannerEDA, the ANFF Design House opens up new scope for device and process design outside of the lab. Available to all ANFF users, it focuses on packages for MEMS, semiconductor processing technologies and devices and 3D visualisation and will assist with device design and development.

Following its launch and initial training workshops in both the Tanner and Coventor Software Suites, Design House will be running an intensive workshop in applications of the Synopsys software in Sydney on Deceber 9 -11.

In a whirl-wind tour, Dr. Mary Ann Maher, the president and CEO of SoftMEMS, and Karen Lujan of Tanner EDA taught workshops in Perth, Melbourne, Brisbane and Sydney during October. Participants received training in the Tanner EDA analogue design tools and MEMS design environment and were given the opportunity to work on a design project under the guidance of Mary and Karen.

Intensive four day workshops were held in both Sydney and Perth on the Coventor software at the start of November. The workshops covered the basics of the suite but also delved into more specific applications such as capacitance response, noise simulation, gas damping and modeling of ultrasonic transducers.

Training for the Synopsys suite will run on December 9-11 at UNSW in Sydney and will include a basic introduction of TCAD concepts and tool usage, as well as sentaurus framework and visualisation, structure editor, process and device simulation, as well as an in-depth and hands-on 180nm CMOS case study. If you are interested in participating in this workshop, please email Design House coordinator, Shan Don.

Successful ARC grant funds new equipment

Through generous contributions by MCN partner institutions, as well as two successful Australian Research Council (ARC) grants, the MCN has been able to install new imaging and characterisation equipment in the Class 10,000 cleanroom. This collaborative approach to funding and operating valuable equipment delivers benefit to all parties, with MCN’s expert staff on hand to run and maintain the equipment in an open-access environment, while minimising duplication.

Through the ARC LIEF scheme (2014), as well as contributions from Monash University, Victoria University and Deakin University, a grant entited “Micro Nanofluidic Characterisation Facility” has funded a Signatone WL-1160 RF/microwave probe station, associated spectral and network analysers, a scanning current microscope and a tensile testing instrument at MCN.

Useful for IV curve generation, measurement of sheet resistance and microwave probing, the Signatone probe station is designed for high-frequency (up to 67 Ghz), high-power, and millimetre wave applications where non-resonant operation is critical.

Its key features include 150mm & 200mm manual X-Y motion control, 50mm x 50mm microscope stage control and separate contact/platen height control with up to 30mm Z motion control of the plate. It holds up to four S-96MW microwave micropositioners and features a vibration isolation table

Applicants on this grant include Associate Professor Adrian Neild, Dr Mainak Majumder, Dr Tuncay Alan, Dr Jean-Michel Redoute, and Associate Professor Wenlong Cheng from Monash University, Professor Stephen Gray, Professor Mikel Duke and Dr Tze Huei Lai from Victoria University, and Associate Professor Abbas Kouzani, Dr Alexey Glushenkov, Professor Lingxue Kong and Dr Xiujuan Dai from Deakin University.

A recent ARC LIEF grant awarded funding for a new Near-field Scanning Optical Microscope at MCN, as well as a shared instrument between Monash University and the Australian Synchrotron and also an upgrade to a system at La Trobe University. For two months a year the spectroscopy system will be coupled to the IR beamline at the Australian synchrotron, to provide full IR spectral coverage available to all Australian and New Zealand scientists. A confocal raman spectrometer will be upgraded to the ultraviolet to provide spectra at less than 150 nanometre resolution. These systems will provide a unique Australian resource for nanoscientists, biomedical researchers and materials scientists requiring molecular information on the nanoscale.

This grant was co-funded under the MCN LIEF policy which contributes cash investment towards collaborative grants and encourages partners to pool resources to acquire cutting edge capabilities.

Applicants on this grant include Professor Donald McNaughton, Professor Douglas MacFarlane, Associate Professor Wenlong Cheng, Professor John Beardall and Dr Qiaoliang Bao from Monash University, Associate Professor David Beattie from the University of South Australia, Dr Evan Robertson, Dr Adam Mechler, Associate Professor Brian Smith, Dr Marc Kvansakul, and Associate Professor Matthew Perugini from La Trobe University, Dr Mark Tobin, Dr Dominque Appadoo and Dr Ljiljana Puskar from the Australian Synchrotron, and Professor Ann Roberts, Dr Shanshan Kou, and Dr Jiao Lin from the University of Melbourne.

MCN thanks all institutions who helped make these grants successful as well as the Australian Research Council for continuing to fund core infrastructure for nanofabrication.

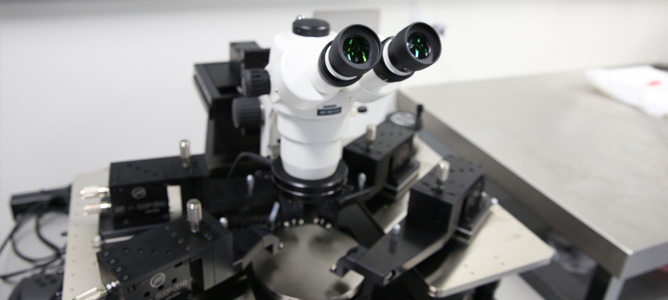

Watch MCN in action – new video online

MCN is pleased to share a new About us video, which captures the mission and vision of the centre and showcases the world-class facilities available to users. Special thanks goes to Monash University for commissioning the video.

2014 holiday and shutdown dates

MCN would like to wish all of our colleagues and friends a safe and happy holiday season! We thank all of our users and collaborators for making 2014 such a successful and exciting year and look forward to continuing this work in 2015.

MCN will close to users and clients on Friday 12th December and will reopen on Monday 12th January. There will be no laboratory access during this time.

New faces at MCN – Abu, Kishan and Chantelle

MCN welcomes three new staff members to our ever-growing team!

Deakin University has recently appointed Dr. Abu Sadek as a technical officer at MCN, responsible for providing focused support for Deakin University researchers who are interested in accessing and utilising the facilities at MCN.

Abu brings with him extensive experience in a variety of microfabrication techniques including: cleanroom processing, photolithography, wet/dry etching, plasma systems engineering, SAW based gas sensors development, thin films deposition and electronic characterisation.

MCN also welcomes Kishan Sarook as quality assurance officer and Chantelle Charlot as executive administrator.

Kishan has a multidisciplinary background in Biomedical Science and a Masters of Business, specialising in Science and Technology. Prior to commencing his role at MCN, Kishan worked for CSIRO as a Business Development Consultant in technology commercialisation. As quality assurance officer, Kishan will be implementing a Quality Management System for ISO certification.

Chantelle joins MCN with over 10 years experience in Executive/Secretariat roles at South East Water. She has completed her certificate in Corporate Governance and Business Administration.

Noteworthy publications

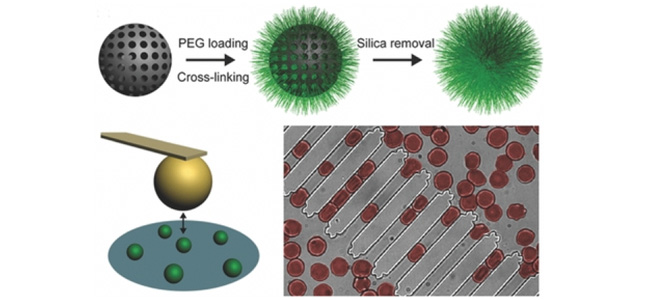

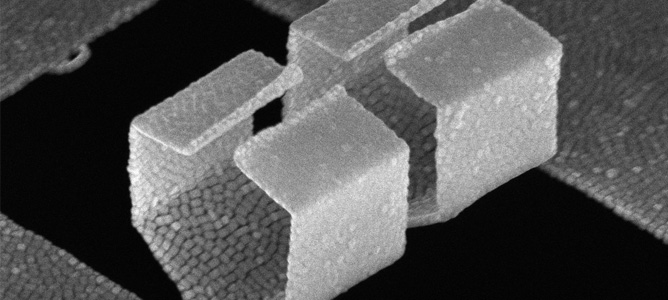

Congratulations to Jiwei Cui et al from the University of Melbourne and the Laboratory for Mechanics of Materials and Nanostructureswho recently published “Super soft hydrogel particles with tunable elasticity in a microfluidic blood capillary model” in Advanced Materials. The paper explores super-soft PEG hydrogel particles with tunable elasticity which are prepared via a mesoporous silica templating method. The deformability behavior of these particles, in a microfluidic blood capillary model, can be tailored to be similar to that of human red blood cells. These results provide a new platform for the design and development of soft hydrogel particles for investigating bio-nano interactions. (see figure 1)

Congratulations to MCN Staff Member, Fatima Eftekhari and Technology Fellows Wenlong Cheng and Qiaoliang Bao from Monash University who recently published “Giant Plasmene Nanosheets, Nanoribbons, and Origami" in ACS Nano. The paper introduces Plasmene— in analogy to graphene—as free-standing, one-particle-thick, superlattice sheets of nanoparticles from the “plasmonic periodic table.” The team report on a general bottom-up self-assembly approach to fabricate giant plasmene nanosheets as thin as ∼40 nm and as wide as ∼3 mm. In conjunction with top–down lithography, such robust giant nanosheets could be milled into one-dimensional nanoribbons and folded into three-dimensional origami. (see figure 2)

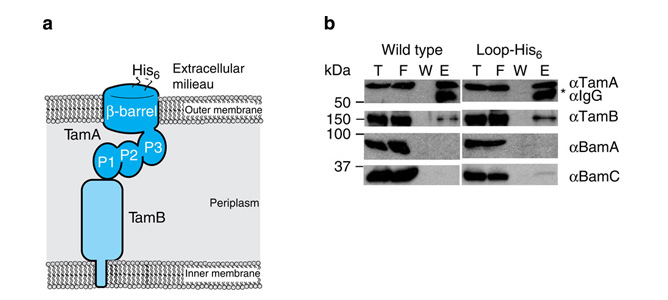

Congratulations to Hsin-Hui Shen et al from Monash University, ANSTO and NIDDk, who recently published “Reconstitution of a nanomachine driving the assembly of proteins into bacterial outer membranes” in Nature Communications. The paper looks at various protein secretion devices of biological membranes which function as nanomachines. The translocation and assembly module (TAM) is a nanomachine required for virulence of bacterial pathogens. The group reconstituted a membrane containing the TAM onto a gold surface for characterization by quartz crystal microbalance with dissipation and magnetic contrast neutron reflectrometry (MCNR). This enabled accurate measurement of protein domains projecting from the membrane layer. The reconstituted system provides a powerful new means to study molecular movements in biological membranes, and the technology is widely applicable to studying the dynamics of diverse cellular nano machines. (see figure 3)

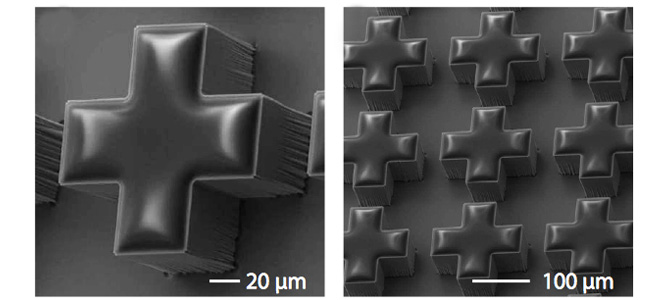

Congratulations to Yong Zhi Cheng et al from University of Adelaide, RMIT University and Huazong University who recently published "Ultrabroadband Plasmonic Absorber for Terahertz Waves" in Advanced Optical Materials. The paper looks at terahertz plasmonics which are used to demonstrate near-unity absorption across a broad spectral range. The absorber comprises a planar array of cross-shaped structures defined by surface etching of doped silicon. Absorbance of over 90% is observed numerically with a relative bandwidth of 90% from 0.67 to 1.78 THz, in reasonable agreement with experimental observation. This ultrabroadband absorption is attributed to two resonance modes supported by plasmonic cavities that are defined by the etched cross structure. This terahertz absorber is single-layered, polarization-insensitive, and exhibits consistent performance across a wide range of incidence angles. The plasmonic-based approach for enhancing absorption is a potential precursor to the realization of efficient bolometric imaging and communications at terahertz frequencies. (see figure 4)