Dr Lachlan Hyde recieves coveted ANFF Frater Award

ANZNMF 2016: call for abstracts

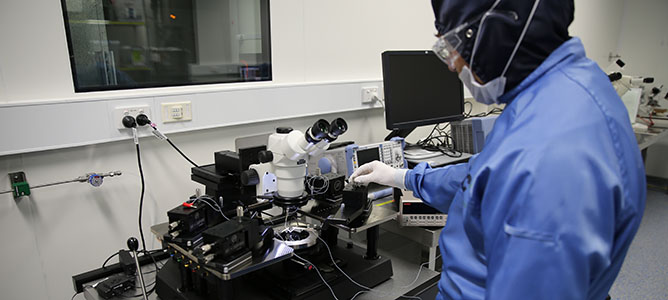

The ANFF-Vic Technology Fellow Ambassador Program

We are excited to announce that a revised ANFF-Vic Technology Fellow Ambassador Program will kick off in January 2016.

ANFF-Vic’s increasingly diverse user base requires comprehensive and flexible training options that cater for different levels of scientific expertise. The technology fellow program will help to proactively build strong user communities around tool sets, and develop new recipes and procedures that can be swiftly disseminated to the broader user community. Fellows will also take an active role in guiding the broad scientific direction of ANFF-Vic.

In return for their efforts, technology fellows will receive access to MCN facilities and equipment, an onsite workspace and other benefits.

The ANFF-Vic technology fellows will be selected by their home institutions within the ANFF-Vic network, and their 12-month fellowship will commence in January 2016.

For more information please contact your home institution, or contact us.

Noteworthy publications

Congratulations to Udo Bach et al from Monash University and CSIRO Manufacturing Flagship, who recently published Copper(I) Iodide as Hole-Conductor in Planar Perovskite Solar Cells: Probing the Origin of J-V Hysteresis in Advanced Functional Materials. The team combined thin continuous perovskite films with copper(I) iodide (Cul) to create organic-inorganic lead halide perovskite solar cells with planar device architecture, and achieved the highest reported efficiency to date for Cul-based planar devices.

Congratulations to Wenlong Cheng et al from Monash University, who had their article Dual-Coded Plasmene Nanosheets as Next-Generation Anticounterfeit Security Labels published by Advanced Optical Materials. Their research focuses on the formation of plasmene nanosheets that can be dual-coded with plasmonic signatures and surface enhanced Raman scattering (SERS) fingerprints to work as anticounterfeit security labels.

Congratulations to Wenlong Cheng et al from Beihang University, Beijing and Monash University, who recently published Free-Standing Bilayered Nanoparticle Superlattice Nanosheets with Asymmetric Ionic Transport Behaviors in ACS Nano. The article documents fabrication of an artificial membrane (based on an asymmetric nanoparticle superlattice bilayered nanosheet) with similar ion transport regulation capabilities as a natural cell membrane.

Congratulations to Adrian Neild et al from Monash University, whose article Two-dimensional single-cell patterning with one cell per well driven by surface acoustic waves was published by Nature Communications. The team have developed a new method for patterning particles and cells using high-frequency acoustic fields, with single cell precision.

Congratulations to Enrico Della Gaspera et al from CSIRO Manufacturing Flagship, who recently published Flash-Assisted Processing of Highly Conductive Zinc Oxide Electrodes from Water in Advanced Functional Materials. The team prepared highly transparent, conductive ZnO films which, when exposed to high-intensity broadband light, resulted in in intrinsically doped films with low sheet resistance. These films can potentially be used as transparent electrodes in light emitting devices.

Congratulations to Yuanhui Zheng et al, who recently published Reversible gating of smart plasmonic molecular traps using thermoresponsive polymers for single-molecule detection in Nature Communications. This work is focused on a plasmonic sensor that can trap single molecules at hotspots for rapid single-molecule detection using surface-enhanced Raman spectroscopy (SERS).

Quarterly recap

MCN 2015 Client Satisfaction survey

We strive to continually improve the quality of our service. Please help by taking a few minutes to complete our annual Client Satisfaction Survey. Please note that all responses are anonymous.

The results of this survey will be published in December 2015. Thanks in advance for your valued feedback!

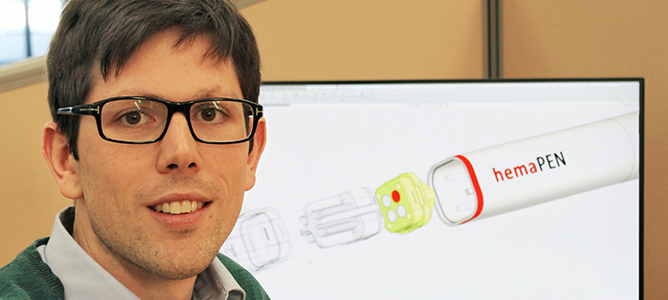

A new approach to blood collection

MCN 2015/2016 holiday closure

MCN will be closed for year-end shutdown work from 21 December 2015 until 10 January 2016. Access during this period will be granted by special application only.

If you have any questions about the holiday shutdown or would like to apply for access during this period, please contact Paul Spizzirri.