Diamond systems produce shining results

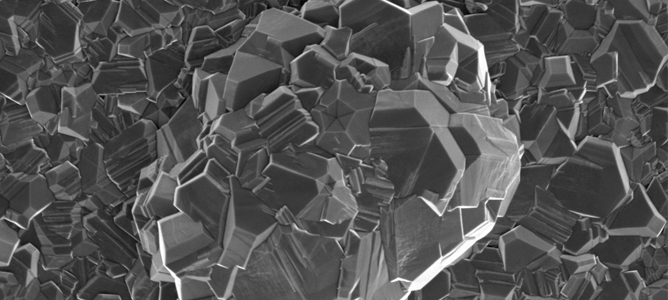

SEM of a high quality diamond film grown at MCN.

MCN’s twin Seki diamond deposition systems have been in operation for almost 12 months, after being launched by Minister Pyne last May. In that time, they have been utilised for some exciting projects by the MCN and University of Melbourne tool experts who have developed a series of effective recipes and growths.

Included in this is the growth of extremely high quality boron doped diamond as well as ultra-pure growth diamond.

Samples of boron doped diamond have been grown with high surface quality and good conductivity for surface-science. Samples of this quality and utility are incredibly difficult to source in the diamond community, and while being tested, these samples have already enabled significant publishable results. The image in above (left) shows a LEED pattern captured at the Australian Synchrotron, where a very high quality surface, with low background scattering and sharp features was observed. The combination of smooth surface and moderate doping levels enabled low temperature measurement in a combination of synchrotron techniques (x-ray absorption, photoelectron and work-function studies).

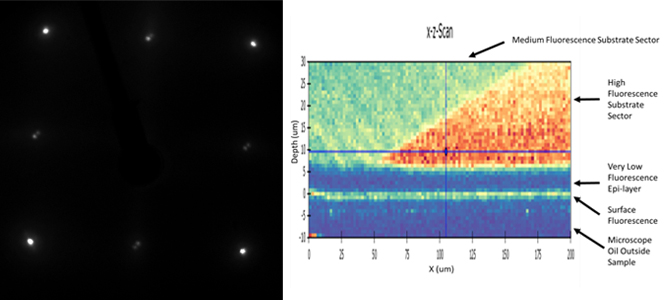

Significant results have also been achieved in the growth of ultra-pure diamond. This was demonstrated using a 10um thick epi-layer grown at MCN, which was then measured using a confocal fluorescence microscope capable of imaging single fluorescent defects in the layer. With a low fluorescence epi-layer on top, a high quality of diamond is demonstrated. Of note, preliminary scans within the epi-layer have identified an average fluorescent defect concentration of less than one defect per 100um3 volume, which represents a bulk concentration of less than 1 part per trillion.

For more information, please contact Lachlan Hyde.